DGP/DJP Series

Commercial & Industrial Air Turnover Systems

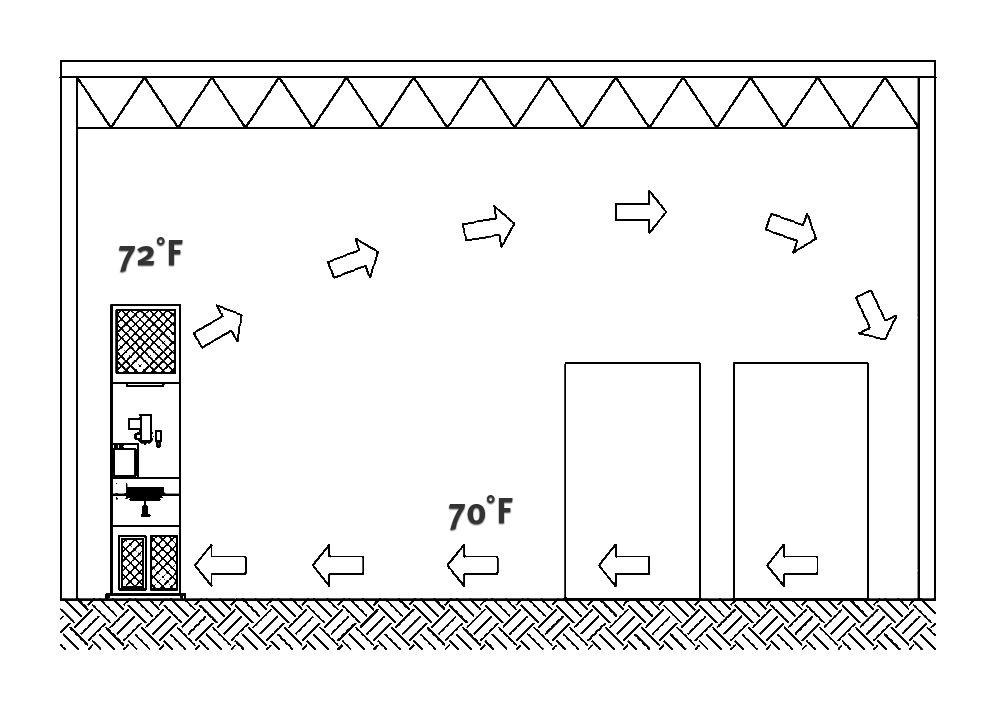

Space Temp Air Turnover Systems offer a solution to the universal problems of heating high bay areas: stratification, uneven temperature, and high energy costs. Other heating systems, most notably unit heaters and infrared heaters, tend to intensify stratification, and provide “spot” heating. These systems cannot provide a uniform space temperature and increase the amount of energy required to heat the space. Learn More

Features

- Air capacity up to 150,000 CFM

- Gas fired heating 100 MBH to 7,500 MBH input

- Indoor / outdoor unit configurations

- Flexibility in MBH and CFM combinations

- Optional heating (hydronic or electric)

- Optional cooling (chilled water or DX)

- Optional outdoor air dampers

- Dedicated Engineered Air NextGen digital controllers

*Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

Space Temp Air Turnover System

Space Temp Air Turnover Systems are designed specifically to provide a uniform space temperature throughout the volume of the space to be heated. Uniform temperature is accomplished by providing a high volume air flow rate, coupled with a relatively low discharge air temperature. This ensures that all areas of the building experience air motion, virtually eliminating stratification. No more bumping the thermostat to make sure “that the cold spot over near the door” is adequately heated, while overheating the balance of the building. Energy costs are reduced, and the comfort level is improved.

FEATURES

- Compact footprint

- One day installation

- One flue penetration

- Constant air circulation

- All units factory tested

- Positive pressure heat exchanger

- High efficiency prop fans are used

- Available with outside air dampers

- Proportional mixing of gas and combustion air

- Internal heat sources are credited to space heating

BENEFITS

- Well suited to shelf or racking systems

- Lowest installation costs

- Reduces potential roof leaks

- Eliminates condensation and provides uniform space temperature and air circulation

- Eliminates start up problems

- No draft inducer required

- Reduces electrical and installation costs

- Can be used to provide ventilation

- Maintain 80% efficiency throughout full firing range

- Reduces energy costs