HRA Series

Packaged Heat Recovery with EngA’s TRP Air to Air Heat Exchanger

Engineered Air’s HRA Series is an energy recovery package specifically designed to reduce the high costs of conditioning ventilation air by recovering a significant portion of the thermal energy from the exhaust air.

Application

Air to air heat exchangers can be employed in any ventilation system to reduce energy consumption. Systems that see the greatest benefit are the ones that have high volumes of hot exhaust air that also need to preheat cold outside air.

With options including auxiliary heating, cooling, flexibility in unit configurations, control systems and protective coatings, HRA units can be effectively used in many situations. Learn More

Features

- Energy savings

- Gas, electric, hot water, steam or glycol heating

- Chilled water or DX cooling coil

- Choice of blower types

- Indoor or outdoor

- Filter options

- Automated optimization of heat exchanger sizing

- Dedicated Engineered Air NextGen digital controllers

Benefits of Heat Recovery

- Heat recovery from exhaust air can significantly reduce the ever increasing operating costs of heating, air conditioning and ventilating

- The initial investment made into the heat recovery equipment is easily recovered because of lower operating costs

- Less environmental pollution due to lower energy consumption

- Added benefit of “air to air” plate type heat exchangers are:

- Virtually complete separation of the air streams

- No moving parts

- No wear, thus low maintenance costs

- Long life

- Not susceptible to breakdowns

*Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

What is an Air to Air Heat Exchanger?

Engineered Air’s HRA Series is an energy recovery package specifically designed to reduce the high costs of conditioning ventilation air by recovering a significant portion of the thermal energy from the exhaust air.

How the Heat Exchanger Works

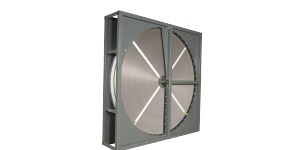

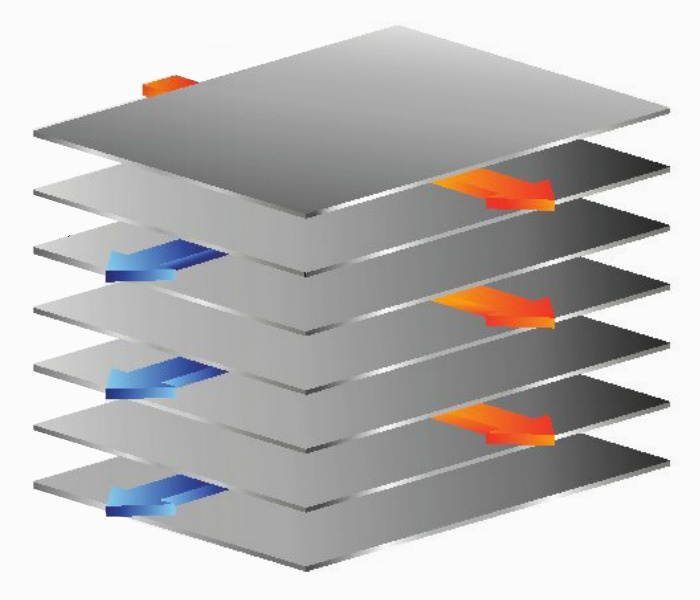

The TRP heat exchanger is a cross-flow fixed plate heat exchanger. Alternate layers of plates are used to form separate exhaust and supply air stream passages (Figure 1).

Figure 1: Alternate Layers of Plates

Sensible heat is transferred from the warm air streams through the separating plates into the cool air streams. Any moisture in the exhaust air stream will increase the heat exchanger’s performance. As the entering outside air begins and continues to cool, the exhaust air temperature will reach its dew point temperature. When the exhaust air temperature is at or lower than the dew point, the moisture in the exhaust air will condense on the surface of the plates giving up energy in the form of latent heat and is transferred to the supply air stream.

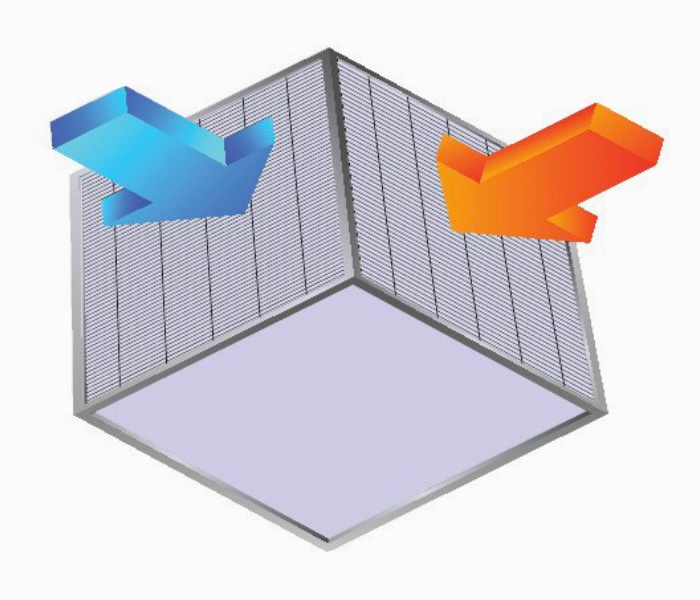

Figure 2: Air Flow

Incoming supply air enters at a right angle to the return air stream (Figure 2). The outside air is either heated or cooled depending on the relative temperatures of the air streams. The Engineered Air TRP heat exchanger is capable of recovering up to 75% or more of the available energy in the exhaust air stream. This high rate of recovery is due to the heat exchanger having only one heat transfer surface of high quality aluminum between the two air streams.

There are no moving parts providing an extremely reliable heat recovery device. Because this is a static device, there is virtually no leakage between air streams. The edges of each plate are folded and sealed with a silicone based sealant. Ribbed, high quality aluminum plates are used providing straight-through air flows minimizing the air pressure drop and thereby minimizing electrical costs of the fans.