HRW Series

Packaged Heat Recovery with EngA’s Total Energy Wheel

Our custom manufacturing facilities allow us to incorporate HRW Heat Wheels into products such as indirect fired gas heating and mechanical cooling equipment.

When providing 100% outside ventilation air the Total Energy Wheel can drastically reduce cooling loads, heating loads and help to control humidity problems in any building. Combined with our state of the art CENCON ER-XM controller we help you maximize building efficiency in both summer and winter applications.

Features

- Energy savings

- Choice of blower types

- Indoor and outdoor

- Chilled water or DX cooling

- Gas, electric or hot water heating

- Filter options

- Automated optimization of models

- Dedicated Engineered Air NextGen digital controllers

*Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

What is a Total Energy Wheel?

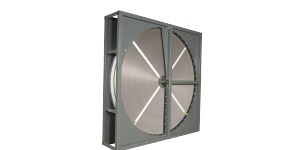

Total Energy Wheels, sometimes referred to as air-to-air rotary heat exchangers, are formed of a substrate of alternating layers of corrugated and flat material wound about a hub to produce a rotor or wheel with a honeycomb structure through which air can pass in contact with a large heat transfer surface. (See Figure 1)

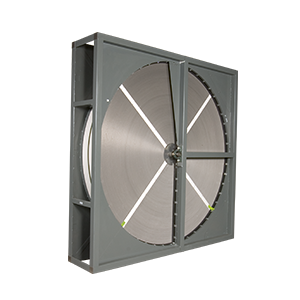

Figure 1: 2700mm Total Energy Wheel

The thermal performance of the wheel, (or, in other terms, the sensible performance) is attained by passing a warm air stream through a semi-circular portion of the rotating wheel, which in turn transfers a large portion of its heat to the honeycombed substrate. As the wheel rotates into the path of a cool air stream, the substrate gives up its heat to that medium, thus warming the cool air. For optimal performance, the two air streams, typically makeup air and exhaust air, pass through the rotary exchanger in a counter flow configuration. For each design wheel, there is a RPM for maximum heat transfer. The wheel can be slowed down if necessary, in order to reduce the rate of transfer.

The latent performance of the wheel is attributed to the desiccant coating adhered to the rotor. The desiccant used on Engineered Air total energy wheels is a zeolite, sometimes referred to as a molecular-sieve. Zeolites, both natural and synthetic, have been employed as adsorbents for gas separation for many years. They have been in use in the HVAC industry since the early 1980s as a desiccant to total energy and dehumidification wheels. The zeolite desiccant consists of a multiplicity of pores which absorb and hold molecules.

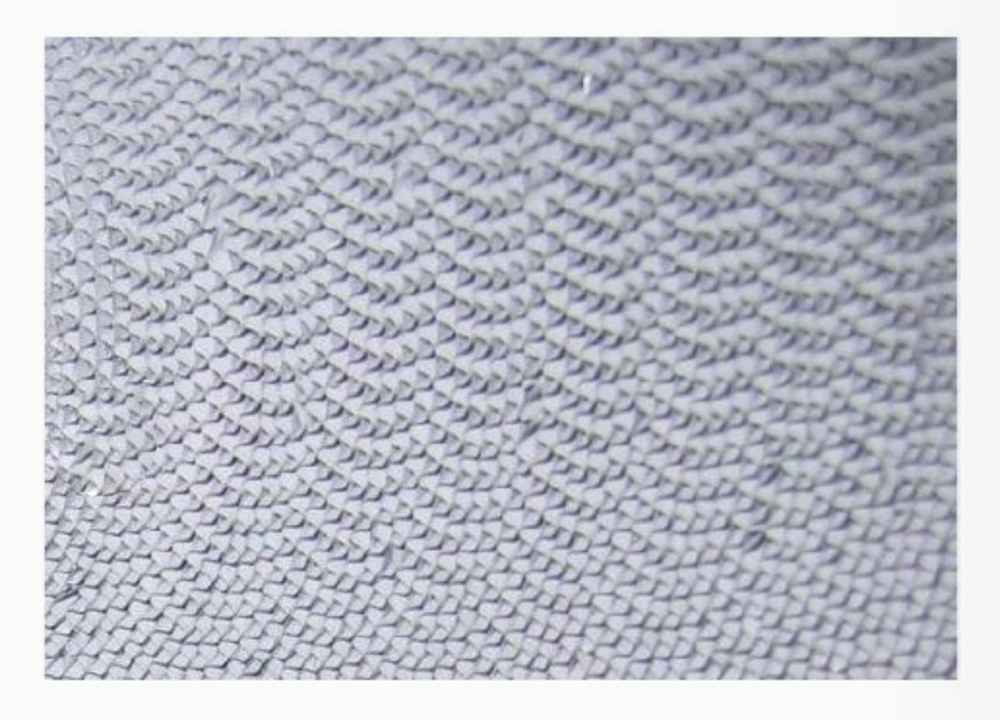

The driving force for adsorption is the vapor pressure differential between the structure of the desiccant particle and the atmosphere around it. Likewise, vapor pressure is also the force for desorption. That effect may be enhanced by heating the air. Figure 2 shows the aluminum substrate on which the desiccant is adhered. Engineered Air employs aluminum for maximum sensible heat transfer and its ability to hold the desiccant coating.

Figure 2: Desiccant Coated Substrate

The benefit of utilizing zeolite as the desiccant in total energy wheels is attributed to the speed with which it adsorbs and desorbs moisture. Other desiccant such as silica gel have greater moisture holding capacity, but take a much longer time to absorb and desorb moisture.

The Engineered Air Total Energy Wheel has the highest sensible efficiency of any of the reclaim products offered by Engineered Air. Total energy reclaim is particularly advantageous in climatic zones where the cooling demand is high ambient humidity. The additional benefit of moisture transfer makes this product a must for any makeup air system, whether it is new or retrofit construction.