HE Series Commercial - Industrial Direct Fired Heaters

The theoretical 100% efficiency should be reduced to 92% due to water vapor being formed as a natural by-product of the combustion process. Units are available with heating capacities up to 14,000 MBH and air capacities up to 100,000 CFM. Units are also available in variable capacity, dual capacity, air curtain, and / or heat recovery configurations.

HE Series

Direct Fired Heaters

Features

- 1,300 to 100,000 CFM

- Up to 25:1 turndown

- Indoor and outdoor configurations

- High Efficiency Green Burn Burners

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

RE Series Industrial Recirculating Direct - Fired Heaters

The theoretical 100% efficiency should be reduced to 92% due to water vapor being formed as a natural by-product of the combustion process. Units are available with heating capacities up to 11,000 MBH and air capacities up to 100,000 CFM. Units are also available in variable capacity, dual capacity, air curtain, and/or heat recovery configurations.

RE Series

Direct Fired Heaters

Features

- Variable Outdoor Air Volume

- 1,600 to 100,000 CFM

- Indoor / Outdoor / Horizontal / Vertical

- High Efficiency Green Burn Burners

Typical Options ( * ) represents standards features

THIS CLASS OF PRODUCT NOT PRESENTLY APPROVED FOR USE IN CANADA

Application of this product requires written approval from the appropriate chief provincial gas inspector.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

DJ Series Commercial - Industrial Indirect Fired Heaters

DJS Series

Our standard model DJS Series indirect fired heating operates with a nominal combustion efficiency of 81%.DJE Series

The DJE Series indirect gas fired unit best matches our previous model series, also with the nominal combustion efficiency of 80%.DJX Series

The most advanced model and highest combustion efficiency rating in the markeplace of 91% is the DJX Series indirect gas fired unit.All DJ Series models feature high turndown burner, Stainless Steel two or three pass heat exchangers which offer longer heat exchanger life expectancy in cold climate operations with 100% outside air operation capability.

The DJ modes are available with heating capacities between 100 and 3,000 MBH. With the proven exclusive Engineered Air DJM Controller all DJ models are capable of 15:1 burner turn down ratios with a range of control options.

DJ Series

Commercial - Industrial Indirect Fired Heaters

Features

- Airflow Rate from 1,000 to 44,000 CFM

- Gas Input Capacities from 100 to 1,400 MBH

- Turndown Ratio up to 15:1

- Indoor and Outdoor Configurations

- Vertical and Horizontal Arrangements

Typical Options ( * ) represents standards features

Case Studies

-

Roxboro House - Calgary Sales Office - 42929 (C34647)

After 28 years one of the original building corridor pressurization units required extensive repairs. Rather than fixing the original unit, the Condo Association started looking for new equipment that would improve operating efficiency and temperature control.

Click to Learn More

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

DG Series Commercial - Industrial Indirect Fired Heaters

The DG Series of industrial indirect fired heaters offers heating capacities between 1,400 and 7,500 MBH. When supplied with the Engineered Air G-TRAC control and our High Turndown Burner, the unit is capable of 20:1 turn down ratios.

Optionally the DG Series units can be configured for high discharge temperature industrial applications.

DG Series

Commercial - Industrial Indirect Fired Heaters.

Features

- 9,100 to 85,000 CFM

- 1,500 MBH to 7,500 MBH input

- Up to 20:1 Turndown

- High efficiency heat exchangers

- Indoor and outdoor configurations

- Vertical or horizontal arrangements

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

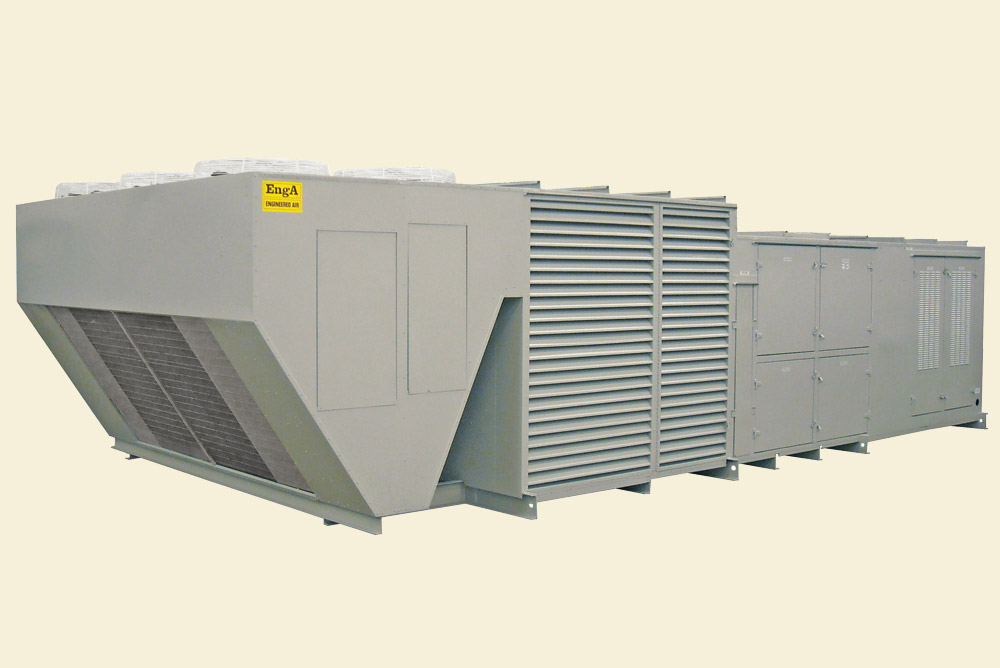

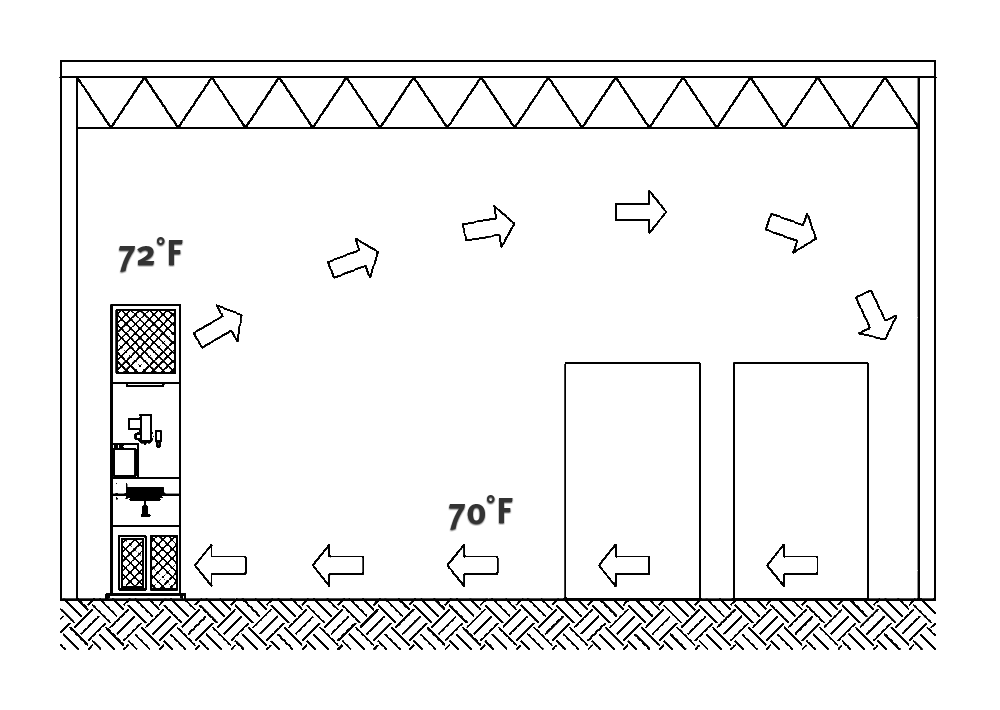

DGP/DJP Series Commercial - Industrial Air Turnover Systems

DJP Series

Commercial - Industrial Air Turnover Systems

Features

- Air capacity up to 150,000 CFM

- Gas Fired Heating 100 MBH to 7,500 MBH input

- Indoor / Outdoor Unit Configurations

- Flexibility in MBH and CFM combinations

- Optional Heating (Hydronic or Electric)

- Optional Cooling (Chilled Water or DX)

- Optional Outdoor Air Dampers

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

LM / LMD Series Commercial - Industrial Air Handlers

The LM series units are designed with forward curved fans, backward inclined fans, airfoil fans, or plenum fans.

LM / LMD Series

Commercial - Industrial Air Handlers

Features

- Made to Order

- Low, Medium and High Pressure Casing Construction

- Indoor and Outdoor Construction

- Multiple Arrangements

- Factory Pre-Wired Control Options

- Energy Recovery Options

- Electric Heat

- Food Grade HVAC Equipment

- Wastewater Applications

Selection Flexibility

The custom design of the LM / LMD Series of air handling units allows component selections to suit the distinctive nature of each application. A variety of fans including forward curved, plenum, air foil and vane axial types are available to accomodate individual power, sound and economic criteria.

A wide choice of models is offered, including horizontal. vertical, draw-thru, blow-thru and multi-zone configurations for indoor and outdoor applications. Heating and cooling requirements can be met with optional hot water, steam, electric, chilled water and refrigerant coils.

A wide array of filtration, humidification and control options complement the line. Click for information about our EngArray

Quality and Reliability

Quality assurance and proven reliability are a result of well designed and rugged units built by experienced and qualified engineers, designers and assemblers.

Quality control inspections and rigorous testings are performed at all stages of manufacturing in Engineered Air's modern plants. LM / LMD units are certified by ETL.

High efficiency heating and cooling coils are produced by Engineered Air with hot water and chilled water coils being approved by AHRI.

LM / LMD units may be factory pre-wired with disconnect switches, motor starters, damper motors and controls, to reduce field installation costs and provide a fully tested and guaranteed product.

Custom Design

The standard LM / LMD Series of air handlers offers selection flexibility and versatility in design. In addition, CUSTOM DESIGNED units are available to accomodate special requirements, including large air flow capacities, physical limitations, hazardous locations, extreme climatic conditions and corrosive atmospheres.

Energy recovery LM / LMD units, incorporating enthalpy wheel, heat pipe, plate and coil runaround systems, provide substantial operating cost savings. An international network of Engineered Air sales offices with technical service support and dedicated personnel are equipped to provide prompt and efficient assistance.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

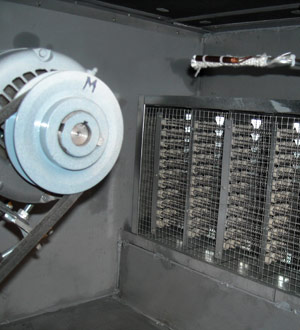

LMK Series Commercial - Industrial Electric Heaters

By staging the heat supplied this control minimizes utility bills while ensuring that the buildings comfort requirements are met. Our air handlers are catalogued with air capacities between 750 CFM and 70,000 CFM - (Custom applications provided up to 150,000 CFM).

LMK Series

Commercial - Industrial Electric Heaters

Features

- 750 to 65,000 CFM

- H-TRAC Controller

- Nickel - Chromium Element Coils

- Indoor and Outdoor Configurations

- Vertical or Horizontal Arrangenments

- Certified Equipment for Hazardous Locations

- Wastewater Applications

Selection Flexibility

The custom design of the LMK series of air handling units allows component selections to suit the distinctive nature of each application. A variety of fans including forward curved, plenum, air foil and vane axial types are available to accomodate individual power, sound and economic criteria.

A wide choice of models is offered, including horizontal. vertical, draw-thru, blow-thru and multi-zone configurations for indoor and outdoor applications. Heating and cooling requirements can be met with optional hot water, steam, electric, chilled water and refrigerant coils.

A wide array of filtration, humidification and control options complement the line.

Quality and Reliability

Quality assurance and proven reliability are a result of well designed and rugged units built bu experienced and qualified engineers, designers and assemblers.

Quality control inspections and rigorous testings are performed at all stages of manufacturing in Engineered Air's modern plants. LMK units are certified by ETL.

High efficiency heating and cooling coils are produced by Engineered Air with hot water and chilled water coils being approved by AHRI.

LMK units may be factory pre-wired with disconnect switches, motor starters, damper motors and controls, to reduce field installation costs and provide a fully tested and guaranteed product.

Custom Design

The standard LMK Series of air handlers offers selection flexibility and versatility in design. In addition, CUSTOM DESIGNED units are available to accomodate special requirements, including large air flow capacities, physical limitations, hazardous locations, extreme climatic conditions and corrosive atmospheres.

Energy recovery LMK units, incorporating enthalpy wheel, heat pipe, plate and coil runaround systems, provide substantial operating cost savings. An international network of Engineered Air sales offices with technical service support and dedicated personnel are equipped to provide prompt and efficient assistance.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

NTM Series No-Through-Metal Air Handler Panels

NTM Series

NTM Air Handling Units

Applications

Engineered Air’s NTM Series air handling unit panels are architecturally designed to complement the building envelope, while providing enhanced thermal insulation, particularly for outdoor units, but also for indoor applications where low temperature air is created within the air handler. The superior joint engineering assures an air tight, moisture resistant enclosure for air handlers and packaged HVAC equipment.

Construction

NTM Series panels are insulated with a non-CFC thermosetting polyurethane insulation that meets model building code specifications. Structural grade steel facings are precisely roll formed and foam insulation is expanded between the metal sheets in a state-of-the-art continuous production sequence that is fully computerized to ensure optimum quality and consistency in every panel.

Insulation

NTM "No-Through-Metal" Series panels with foamed polyurethane insulation is offered in 2” thickness. 4” thick panels are available at extra cost, an extended delivery.

Facings

NTM Series panels are faced with 26 gauge stucco embossed galvanized steel to ASTM-525 G-90 designation. Base steel shall be structural quality to minimum Grade A 33,000 psi, conforming to ASTM A-446. Optional panel facings of Galvalume, aluminum or stainless steel are available at extra cost and extended delivery.

Coating Systems

NTM Series panels are primed both sides with a 0.2 mil primer and finished on one or both sides as specified, with one of the following finishes:

- Electrostatically applied alkyd enamel: supplied in Aluminum Gray as standard, or colour to suit.

- Two part epoxy enamel with clear coat glossy finish. Approved for food contact areas in a limited range of colours.

Fire

Meets special requirements of model building codes and is certified and approved by the following authorities:

- UL

- Underwriters Laboratories Inc.

- ULC

- Underwriters Laboratories Canada

- FM

- Factory Mutual

- WH

- Warnock Hersey

- NYFC

- New York State Toxicity Standard

- FM-4880

- Class 1 Fire Rating

- ASTM-E84

- Flame Spread: 17 | Smoke Developed: 97

- ULC-S102

- Flame Spread: 22 | Smoke Developed: 67

- UBC 17-6

- Passed multi-storey test with standard panels

Thermal Properties Standard 2” panel

- Transmission

- 0.061 BTU/hr × ft² × °F (including air films)

- Resistance

- 15.6 °F × ft² × hr/BTU (panel only - no air films)

Vapor Barrier

- ASTM E-238

- Air Infiltration: 0.0015 CFM/ft² at 20 psf

- ASTM E-331

- Water Penetration: "0" at 20 psi

Structural

- ASTM E-72

- Vacuum chamber tested for wind and suction load deflections on wall assemblies

- ASTM E-72-9

- The panel achieved a vertical load bearing capacity on standard width to maximum 19,800 lbs. compressive force at 0.06” deflection

- Fatigue Test

- Standard panels were tested for long term deflection failure. The panels exceeded 2 million cycles without failure or deformation

- Bond Strength

- The panel was tested for Tensile Bond Strength of the metal-to-foam interface to more than 1200 lb. force without delamination.

| Thickness | Span (feet) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |

| 2” Std. | 71.1 | 56.1 | 45.2 | 37.1 | 30.9 | 25.9 | 22.0 | 18.7 | 16.2 | 14.0 | 12.1 | 10.4 | ||||

| 4” Opt. | 121.9 | 98.8 | 82.2 | 69.6 | 59.8 | 51.9 | 45.4 | 40.0 | 35.5 | 31.6 | 28.2 | 25.2 | 22.5 | 19.8 | 17.9 | 15.9 |

Note: to determine static pressure within cabinet, multiply allowable loading in PSF by 0.192.

Example: 2’ panel with a 10 foot span can withstand an internal static pressure of 25.9 × 0.192 = 5.0”w.g.

If snow load or internal static pressure exceeds the unsupported span length,

an intermediate structural support will be provided to reduce excessive deflection.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

FWE Series Commercial & Industrial Mechanical Cooling / Heating Units

Standard configuration for an FWE series product includes forward curved fans but can be modified to include Backward Inclined fans, Airfoil fans, Plenum fans, etc...

FWE Series

Commercial & Industrial Mechanical Cooling / Heating Units

Features

- Multiple staged compressors and / or modulating compressor

- Energy efficiency verified models available

- R-407C, R-410A and optional R-134a refrigerants

- Direct or indirect gas-fired heaters (high efficiencies and turndowns)

- Hydronic and electric heating coils

- Total or sensible energy recovery components

- Custom fans - EngArray

- Your equipment solution for sustainable buildings

- 6 through 120 tons of mechanical cooling

- 1,600 to 56,000 CFM air volumes

- Custom units for non-catalogued capacities

- Multiple independent compressor circuits

- Dedicated EngA TRAC Controllers

- Unit base fabricated from steel channel

Typical Options ( * ) represents standards features

Case Studies

-

Grant Bone and Joint Revitalization Project - Columbus, Ohio - D5582 (TC-597)

The Grant Bone and Joint Center building was originally a downtown Holiday Inn that over the years had been modified. As a former hotel the facility did not have any existing mechanical rooms and space on the roof was already limited with the existing chillers and air handling equipment.

Click to Learn More

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

UPEW Series Water Cooled Packaged Air Conditioners

The UPEW Series lend themselves to small office buildings, commercial retail space and food service areas where the use of air-cooled equipment is not feasible. Water-cooled air conditioners provide significantly higher Energy Efficiency Ratios (EER).

Features

- Pre-wired, water cooled packaged air conditioners

- single & multiple quiet running gas cooled hermetic scroll type compressors

- Resiliently mounted forward curved supply air blowers

- Tube-in-tube refrigerant condensers

- Sound treated compressor-condenser compartment

- Two inch deep MERV 7 pleated filters

- Vertical or horizontal (back or front) fan discharge

Available Options

- Air Handler

- Airfoil fans (DIDW or SISW), plenum fans

- Compressors

- Hermetic reciprocating

- Condensers

- Cleanable shell and tube type, brazed plate stainless steel

- Evaporators

- Alternate tube circuiting

- Filters

- Cartridges, bags, HEPA and chemical types

- Free Coolers

- At lower outdoor temperatures, a separate hydronic coil to use with cooling towers

- Glycol Condensing Circuits

- Selections available

- Heating Coils

- Hydronic or electric

- Variable Air Volume

- Variable speed drives, inlet vanes

- Silencers

- Integral return air silencers, add-on supply air silencers

- Sound Treated Casings

- Extra heavy wall, 3-lb/ft3 rigid insulation, 24 ga. perforated liner

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

PD Series Pool De-Humidifier

Our PD Series of Pool Dehumidifier units cool, dehumidify and reheat air from pool areas. They can also incorporate heat recovery of the exhaust air for additional operating cost savings.

PD Series

Indoor / Outdoor Pool De-Humidifiers

Features

- Indoor or outdoor models are available

- Corrosion resistant Heresite coating is used on DX cooling and condenser coils

- Compressor energy (heat) is reclaimed and used to heat pool water

- Latent heat loss from the pool a water evaporates is reclaimed and rejected back into pool water and the pool supply

- Auxiliary remote air cooled condensers are available which allows the system to provide space air conditioning

- A variety of control options are available

Options

- Return air fans and/or mixing boxes can be provided when required.

- Auxiliary Engineered Air heating components (DJ, DG, electric, water, or steam coils) can be added to give a complete package.

- Free cooling packages including motorized dampers (outside air, return air and exhaust air), as well as all economizer controls are available.

- Whirlpool de-superheaters (selected for higher pool water temperature) are available.

- Exhaust air heat reclaim systems using air to air, or heet pipe coils air available.

Benefits

Evaporating from the surface of an indoor swimming pool causes two major concerns. The first and most obvious problem relates to the resulting high relative humidity level.

During periods of low outside air temperatures, high indoor humidity causes problems with condensation and frost on windows.

A more serious problem could result if moisture penetrates into the building structure, where it could condense and freeze thereby causing structure damage.

The second major concern is heat loss from the surface of the swimming pool. As moisture evaporates from the surface of the pool, a large amount of heat is lost as the latent heat of evaporating is carried away by the moisture. If the humid air was simply exhausted, all of this latent heat would be lost and would have to be replaced by heating the pool water.

This discussion makes the benefits of an Engineered Air PD Series pool de-humidifier obvious. These benefits can be summarized as follows:

- Reduced pool heating costs due to reclamation of latent heat of evaporating from pool surface.

- Reduced space humidity levels prevents possible structural damage due to condensation.

- Space comfort conditions are also obviously improved by the lower relative humidity level. If a remote (outdoor) air-cooled condenser is used, the resulting space cooling ability also has obvious benefits.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

CD Series Ice Rink De-Humidifiers

CD Series

Ice Rink De-Humidifiers

Application

A common problem encountered in skating or curling rinks is fog and / or moisture condensing and dripping from the structure. This occurs during periods when the space temperature is low and moisture content of the air relatively high. Condensation problems can occur throughout the year but more frequently occur during the spring and fall seasons.

In pool environments, outside air can often be used to condition the space and reduce the moisture level. This approach cannot be used in a rink environment because the outdoor air contains moisture with a higher dewpoint level than the indoor temperature of the rink. As a result, bringing in outdoor air for ventilation only adds to the fog and condensation problems.

The solution is to remove moisture from the ice rink air by using an Engineered Air dehumidifier. Our CD Series is one option. One alternative is the DWD Desiccant Gas Fired De-humidifier by Engineered Air.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

FW/HE Series Mechanical Cooling / Direct Fired Makeup Air Units

FWE/HE units are available with side, up, or down discharge. Roof curbs are available where required.

FW / HE Unit

Direct Fired Makeup Air with Mechanical Cooling

Features

- Energy efficiency verified models available

- R-470C, R-410A and R-134a refrigerants

- Multiple independent compressor circuits

- Custom units for non-catalogued capacities

- Dedicated Engineered Air TRAC controllers

- EER ratings meet of exceed ASHRAE 90.1 requirements

- High efficiency Green Burn burner

- Packaged direct fired burner with mechanical cooling

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

FW/DJ Series Mechanical Cooling / Indirect Fired Makeup Air Units

FW/DJ units are available with side, up or down discharge. Roof curbs are available where required.

FW / DJ Unit

Mechanical Cooling / Indirect Fired Makeup Air Unit

Features

- Energy efficiency verified models available

- R-407C, R-410A and R-134a refrigerants

- Multiple independent compressor circuits

- Custom units for non-catalogued capacities

- Dedicated Engineered Air TRAC controllers

- EER ratings meet or exceed ASHRAE 90.1 requirements

- Indirect gas fired heat exchanger capable of 100% makeup air

- Packaged indirect fired burner with mechanical cooling

Typical Options ( * ) represents standards features

Applications

The FW/DJ Series is excellent in providing makeup air for hallway pressurization, industrial facilities, food processing, commercial kitchens, health care, laboratories, athletic facilities or anywhere there is a need to heat and cool 100% outdoor air.

Components

- Burner / Blower

- Refer to DJ Series Indirect Fired Heaters.

- Compressor

- Available in multiple hermetic scroll or reciprocating models that are similar to the FW Series cooling units.

- Evaporator

- Alternate tube coil that is individually selected to meet specific conditions of operation.

- Controls

- Refer to the Control Section or contact your Engineered Air Sales Representative

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

CU Series Air Cooled Condensing Units

CU Series

Air Cooled Condensing Unit

Features

- Multiple staged compressors and / or modulating compressor

- Energy efficiency verified models available

- R-407C, R-410A and optional R-134a refrigerants

- Single circuited hermetic scroll compressors

- Tandem circuited hermetic scroll compressors available

- Your equipment solution for sustainable buildings

- 3 to 120 ton units

- Custom units for non-catalogued capacities

- Multiple independent compressor circuits

- Indoor and outdoor configurations

- Unit base fabricated from steel channel

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

FW/EC Series Packaged Air Conditioners with Evaporative Condensers

The FW/EC series of air conditioners utilizes the benefits of evaporative cooling in the condenser, allowing condensing temperatures in the range of 100°F to 110°F, even with ambient dry bulb temperatures at 100°F or over, as long as the web bulb temperature of the outside air is at 80°F or lower.

Features

- Meets or exceeds ASHRAE 90.1 efficiencies

- Supply air temperatures as low as 44°F

- Walk-in compressor section

- Excellent serviceability

- Full range of heating accessories

- Full range of filtration accessories

- Minimized unit footprint

Applications

Lower condensing temperatures with the resulting higher EER's mean lower operating costs for the owner. Even when operating cost is not a concern, (seldom the case), building code authorities may impose electrical energy input limits on the air conditioning system, most often along the lines laid out in the ASHRAE Standard 90.1.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

MZ Series Commercial - Industrial Heating and Cooling

Reduced energy consumption through:

- up to 15:1 turndown with gas heat

- multiple compressors

- improved control systems

MZ Series

Commercial - Industrial Heating and Cooling

Features

- Hot Deck available with Gas, Hydronic or Electric heat

- Wide range of gas fired heating capacities

- Available with DX or chilled water cooling

- Multiple Compressors

- Independently piped and circuited compressors

- Hot gas bypass on lead compressor

- 15:1 turndown on indirect gas fired hot deck

- Hot deck temperature inversely reset from outdoor ambient

- Z bar Roof Curb mating flanges

- Interface with BMS (Build Management Systems) or existing 135 OHM room thermostats

- Parallel flow hot / cold decks

- Blow through cold deck

- Hinged front access on unit discharge

- Integrating increased cooling capacity on existing roof curbs

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

SH Series Commercial - Industrial Gas Fired Steam Humidifier

Dedicated Engineered Air controls, specifically designed for EngA Burners, are used to achieve up to 15:1 fully modulating turndown ratio. The ability to modulate the combustion process, while maintaining or increasing the efficiency throughout the turn down range, results in the lowest energy cost per pound of steam produced.

This recognized combination of Engineered Air TRAC controller, burner and heat exchanger is further enhanced to achieve minimum capacity duration at high altitudes.

These proven technologies are the heart of the Engineered Air SH Gas Fired Humidifier. Learn More

SH Series

Commercial - Industrial Gas Fired Steam Humidifier

Features

- Up to 650 pounds of steam per hour

- Engineered Air Combustion Technology

- Up to 15:1 fully modulating turndown ratio

- High efficiency heat exchangers

- Low profile arrangement

- Large tank for less interruption

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

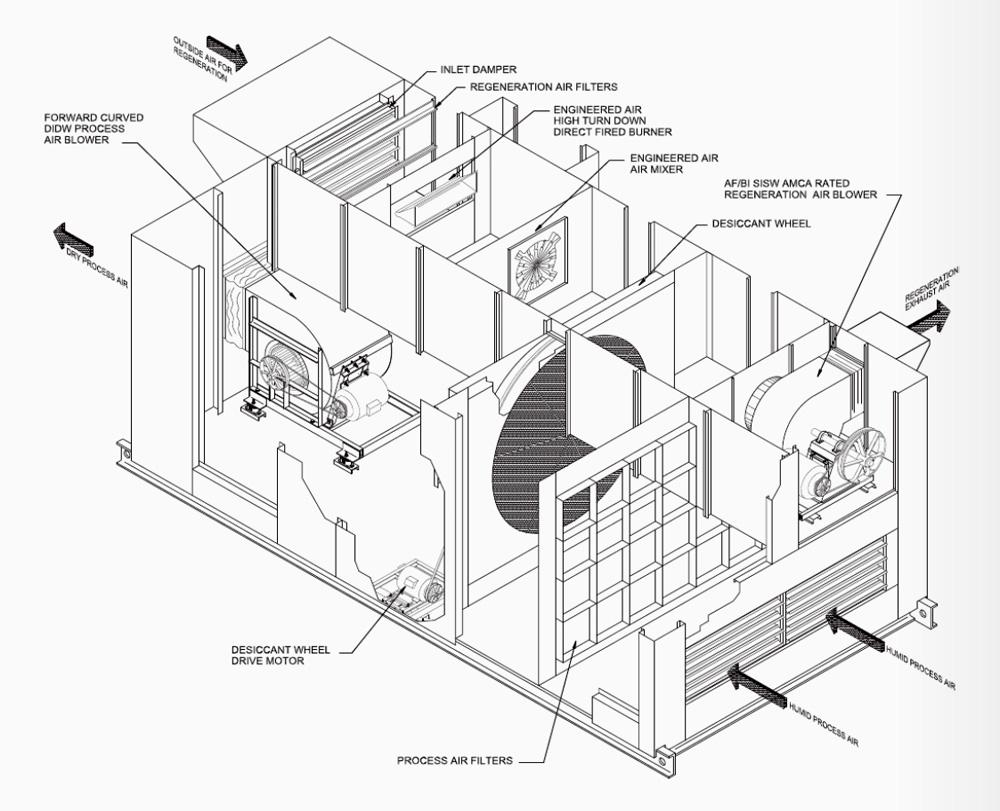

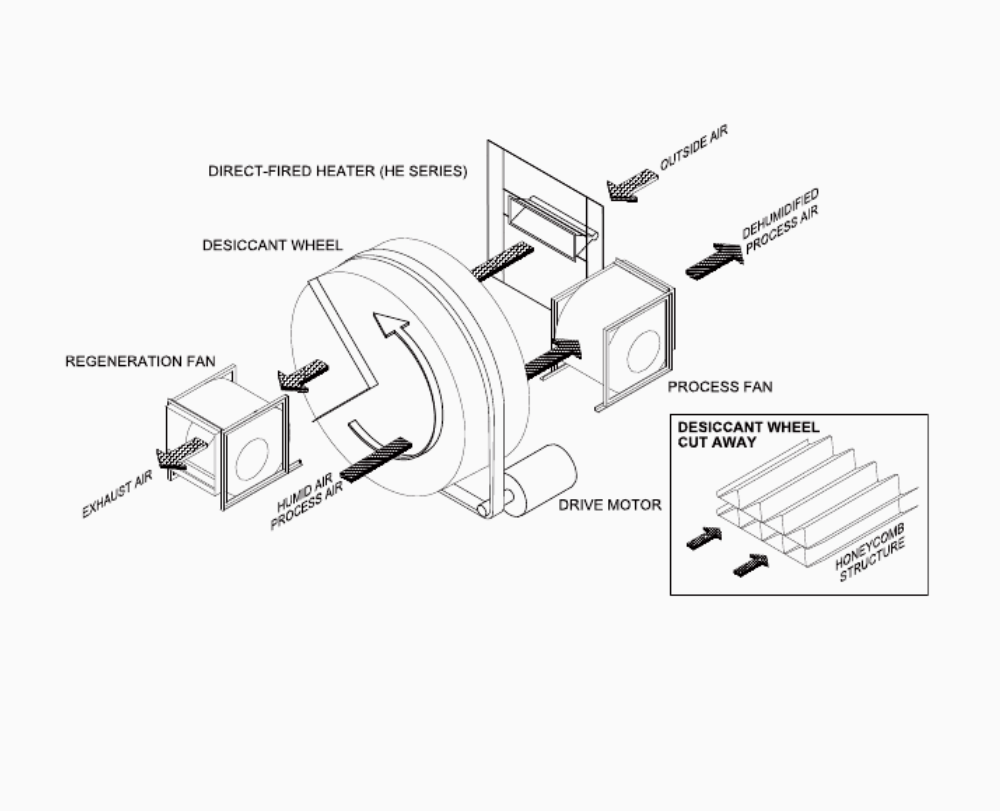

HE/DWD Series Gas Fired Desiccant De-humidification Unit

Features

- Indoor and outdoor models are available.

- 1500 to 15000 CFM process air.

- Lightweight, thermally and chemically stable, high performance and low maintenance desiccant wheels using activated silica gel for effective moisture and adsorption even in low humidity conditions.

- Sizes available to dehumidify the process air below 40°F dewpoint and remove up to 470 lb/hr moisture @ 60°F DB / 90%RH.

- High efficiency Engineered Air 20:1 high turndown Green Burn direct-fired burner used for desiccant wheel regeneration.

- EngA air mixer enhances moisture removal by providing thorough air coverage onto the face of the desiccant wheel.

Applications

- Ice rink

- Critical temperature storage such as library archive storage

- Production lines for pharmaceuticals

- Production lines for plastic products

- Dehumidification at fertilizer plants

- Food drying

- Museum

- Environmental test room

- Powder filling applications

Fundamentals of Operation

- The Engineered Air HE/DWD Series gas fired desiccant dehumidifier uses vapor pressure differential to absorb moisture on the relatively cool process air side and then drive this moisture off in the hot regeneration airstream. The process air is hence dehumidified.

- The desiccant wheel rotates constantly through the process air and the regeneration airstreams.

- The ambient regeneration air is heated by an Engineered Air direct fired burner (HE Series). The water molecules transferred from the process air are then discharged to the ambient.

Benefits

- Gas fired dehumidification units do not have a DX coil and inherent freezing problems associated with a low temperature DX coil. With mechanical cooling dehumidification, the condensed moisture will freeze on the surface of the evaporating coil when the coil surface is below 32°F as is sometimes necessary to reach low dewpoint levels. As a result, the minimum achievable dewpoint is limited by frosting on the DX coil.

- Lower operating cost — especially in areas where the electricity cost is high and the natural gas cost is low. Mechanical cooling compressors require a significant amount of electricity to provide dehumidification.

- No water condensation issues — the mechanical cooling dehumidification evaporator will condense water which will promote undesired microbial growth in the system/

- Lower maintenance cost — gas fired desiccant dehumidifier has fewer components to service than mechanical cooling dehumidification units.

Options

- Mixing boxes can be provided if required.

- Auxiliary Engineered Air cooling components (FW mechanical cooling or chilled water coil) can be added to re-cool dehumidified process air to neutral condition.

- A sensible heat wheel can be added to re-cool the process air down stream of desiccant wheel and preheat the regeneration air upstream of Engineered Air's burner.

- High temperature process exhaust heat (approximately 125°F to 280°F) from the building, steam or electric heat, if available, can be used in the regeneration air to reduce the required heating capacity or eliminate the direct fired burner.

- A cooling coil (DX or chilled water) could be used as an option to re-cool the warm dehumidified air.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

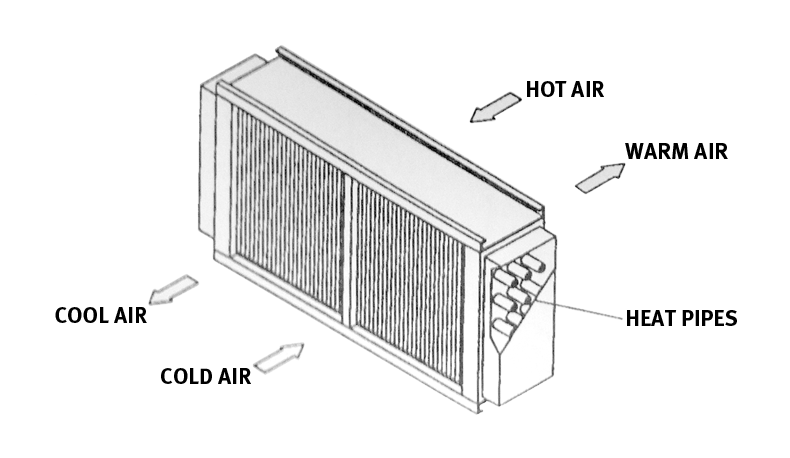

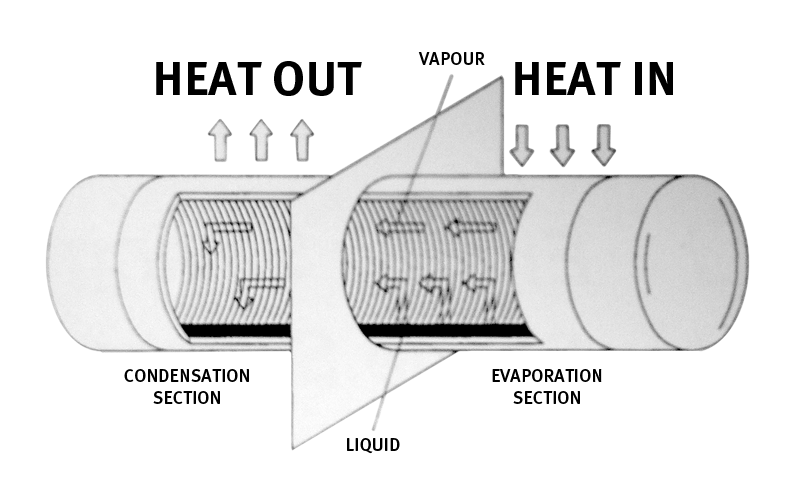

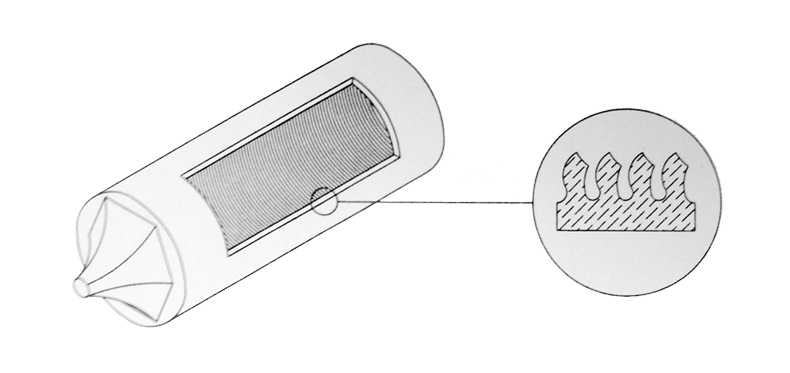

HRP Series Industrial Air to Air Thermal Recovery Units with QDT Heat Pipe

HRP Series

Industrial Air to Air Thermal Recovery Units with QDT Heat Pipe

Features

- Energy Savings

- Choice of Blower Types

- Gas, Electric, Hot Water or Glycol Heating

- Chilled Water or DX Cooling Coil

- Indoor and Outdoor

- Filter Options

- Computerized Heat Pipe Sizing

The Practical Heat Exchanger for Industrial Heat Recovery

Although industrial process exhaust contains valuable thermal energy, it generally contains contaminants in the form of condensables, corrosives or particulates. These complicate energy recovery efforts.

An effective heat exchanger must be able to separate the BTUs from the dirty air. This requires both a versatile heat exchanger design plus the engineering know-how and experience to properly apply it. Engineered Air, with its HRP Series of Packaged Heat Recovery units, offers you both.

The HRP Series is an air-to-air heat pipe heat exchanger specifically designed for the complexities of industrial heat recovery.

It has the following advantages:

- No moving parts

- Nothing to wear out, so the HRP Series has an extremely long lifetime with no mechanical maintenance.

- No cross

contamination - Sealed partition separates the two airflows preventing contamination of the fresh air by the exhaust.

- Self-contained

- Requires no external power of operation.

- Minimum cleaning

- Specially designed with fewer fins on the dirty process exhaust side than on the clean fresh air side. Industrial HRP Series have flat, continuous plate fins to provide see-thru, clean-thru™ capability. Built-up dirt can easily be flushed during cleaning.

- Size flexibility

- A wide range of sizes are available that can be installed singly or as modules to meet the requirements of almost any airflow system.

- Performance

flexibility - A wide range in the number of rows of heat pipes are available to provide desired recovery performance while still affording minimum cleaning maintenance. Buy only the amount of recovery you need.

- Material flexibility

- Available in different materials of construction to accommodate various corrosive effluents. Heresite® protective coating is also available for temperatures up to 400°F

- Compact

- HRP Series range from 6 to 16 inches deep in the direction of flow which reduces space required, lowers installation costs, provides ease of handling and simplifies cleaning.

- Structurally sound

- Constructed of heavy gauge materials to easily withstand the rigors of industrial environments.

In short, the Industrial HRP Series has the versatility needed to meet the varied conditions of industrial heat recovery. In addition, Engineered Air has the knowledge and experience to successfully apply this versatility to solve your heat recovery problems.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

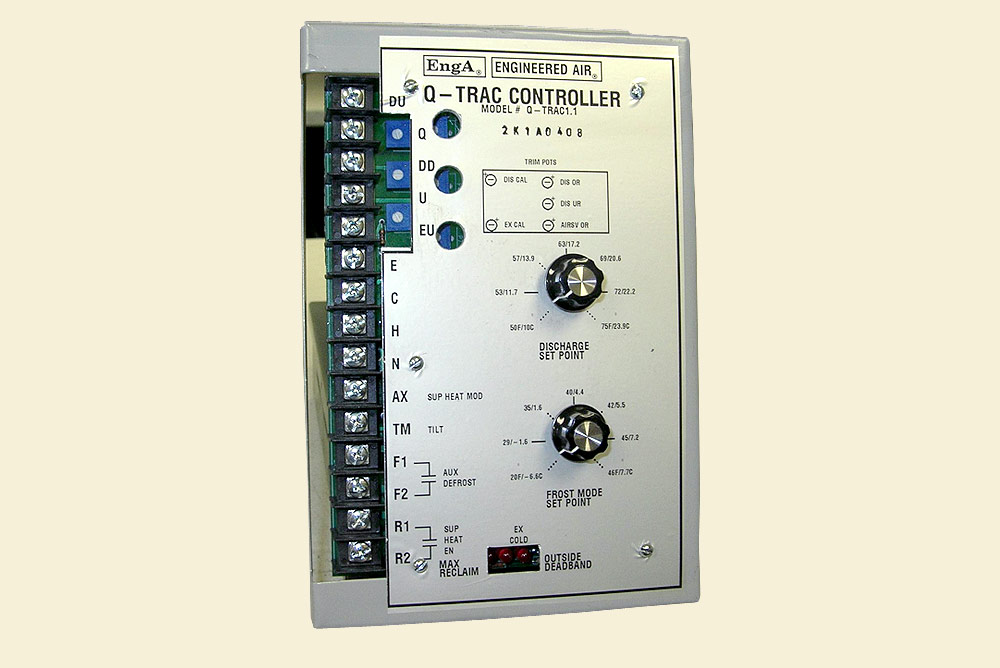

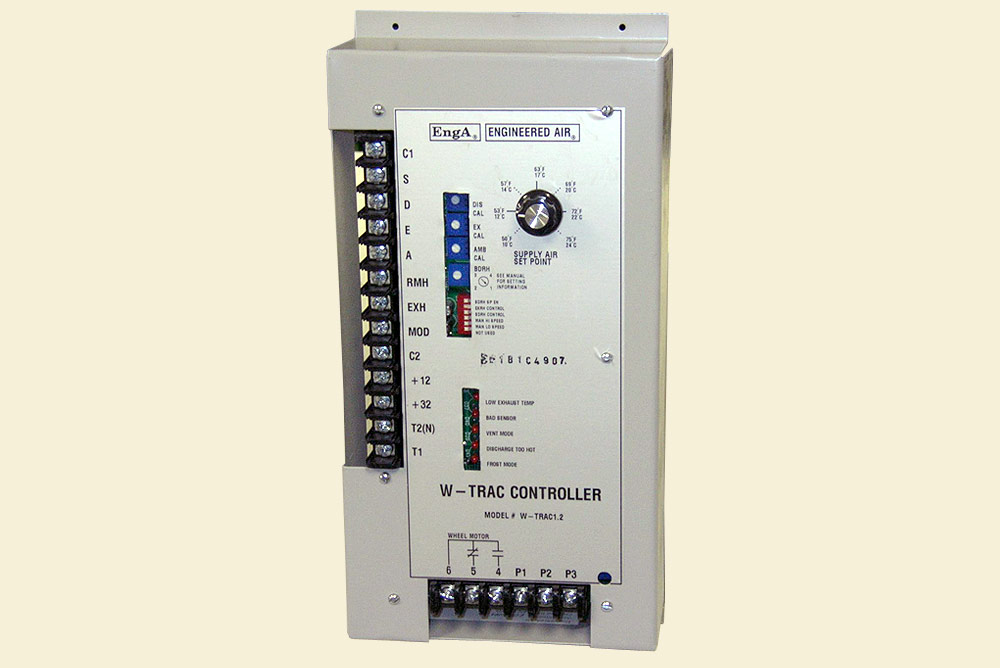

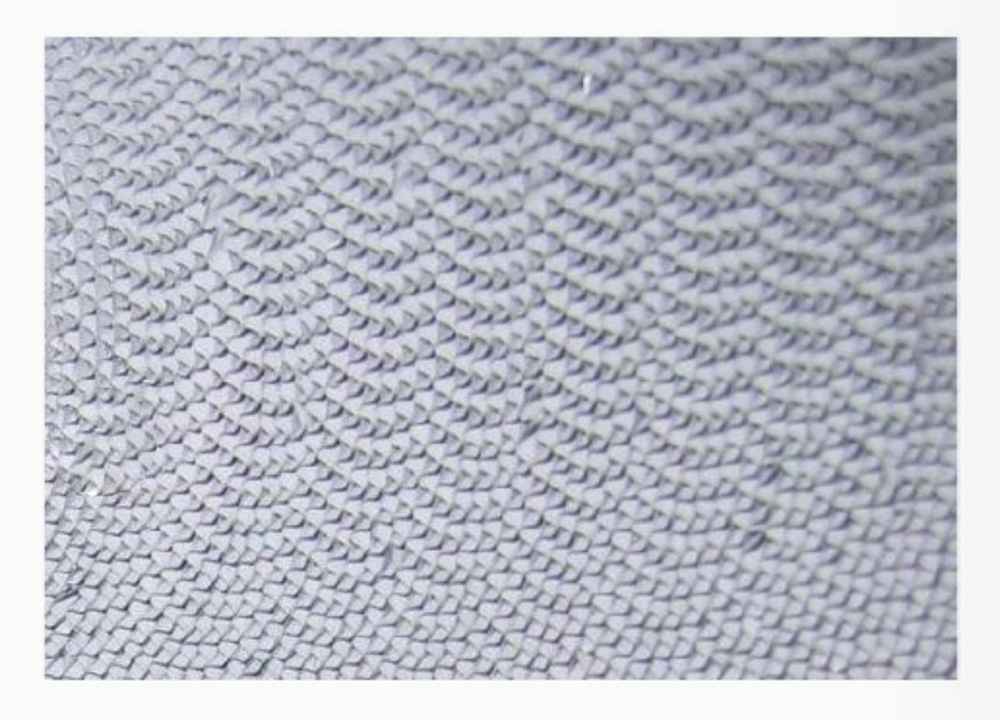

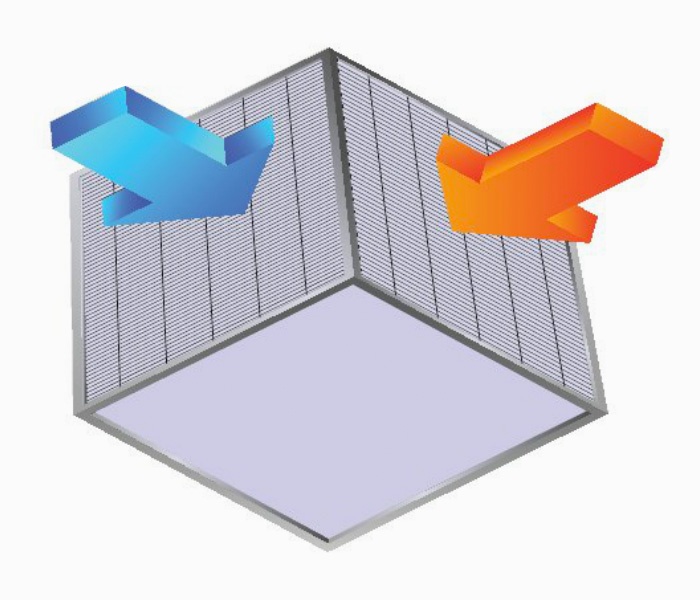

HRW Series Packaged Heat Recovery with EngA's Total Energy Wheel

When providing 100% outside ventilation air the Total Energy Wheel can drastically reduce cooling loads, heating loads and help to control humidity problems in any building. Combined with our state of the art W-TRAC controller we help you maximize building efficiency in both summer and winter applications. Learn More

HRW Series

Packaged Heat Recovery with EngA's Total Energy Wheel

Features

- Energy Savings

- Choice of Blower Types

- Indoor and Outdoor

- Chilled Water or DX Cooling

- Gas, Electric or Hot Water Heating

- Filter Options

- Computerized Wheel Sizing

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

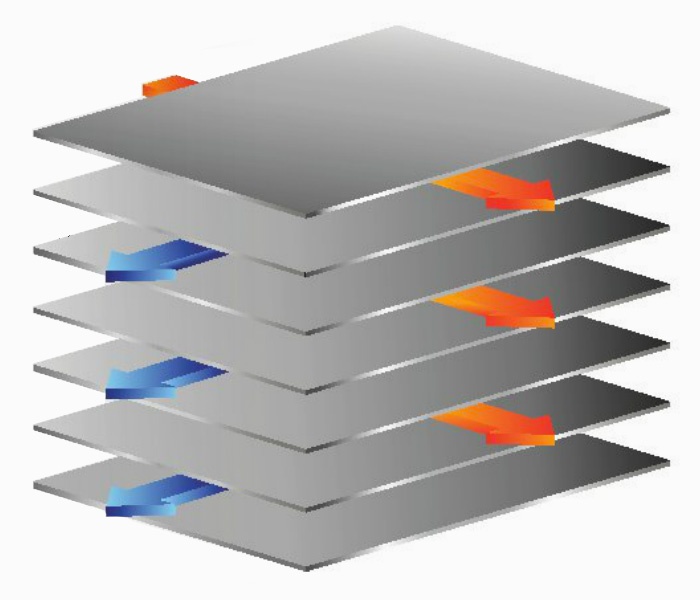

HRA Series Packaged Heat Recovery with EngA's TRP Air to Air Heat Exchanger

Application

Air to air heat exchangers can be employed in any ventilation system to reduce energy consumption. Systems that see the greatest benefit are the ones that have high volumes of hot exhaust air that also need to preheat cold outside air.

With options including auxiliary heating, cooling, flexibility in unit configurations, control systems and protective coatings, HRA units can be effectively used in many situations. Learn More

HRA Series

Packaged Heat Recovery with EngA's TRP Air to Air Heat Exchanger

Features

- Energy Savings

- Gas, Electric, Hot Water, Steam or Glycol Heating

- Chilled Water or DX Cooling Coil

- Choice of Blower Types

- Indoor or Outdoor

- Filter Options

- Computerized Heat Exchanger Sizing

Benefits of Heat Recovery

- Heat recovery from exhaust air can significantly reduce the ever increasing operating costs of heating, air conditioning and ventilating

- The initial investment made into the heat recovery equipment is easily recovered because of lower operating costs

- Less environmental pollution due to lower energy consumption

- Added benefit of "air to air" plate type heat exchangers are:

- Virtually complete separation of the air streams

- No moving parts

- No wear, thus low maintenance costs

- Long life

- Not susceptible to breakdowns

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

HRG Series Glycol Run Around Heat Reclaim System

Combined with proven Engineered Air heating systems to augment the reclaim system:

- HE Series

- Direct Fired Burners

- HE-K Series

- Electric Resistance Heaters

- DG Series

- Industrial Gas or Oil Burners

- LM Series

- Hydronic Heating

Utilize the Engineered Air computerized coil selection process to optimize the fluid handling system components for maximum efficiency and minimum cost.

HRG Series

Glycol Run Around Heat Reclaim System

Optional Features

- Piping enclosures, insulated and weather proofed for outdoor installations

- Pipe insulation

- Exhaust coil wash-down plenum and drain pan

- Steel tube, aluminum fin coil

- Special dimensions and configurations

Where should HRG Series be used?

- Commercial and industrial buildings, where exhaust and makeup are required for many hours of the year, the more hours the better.

- In installations where exhaust air temperatures are from 80°F to 200°F and where the air is not particularly corrosive. Exhaust air temperatures below 80°F tend not to be an economic source of heat, particularly where outdoor air temperatures are sub zero, and the possibility of circulating glycol at temperatures below 32°F exists, thus creating certain frosting conditions on the exhaust coil, which is a dehumidifying coil. While the control system can automatically prevent frost from forming, the efficiency of the system is low while operating in a "frost prevention" mode and energy savings may be less than anticipated.

- Areas of the country where the normal energy source is relatively expensive will be attractive for heat reclaim systems: the relative cost of energy seems to be rising at an alarming rate throughout all of Canada, so few areas will not find the reclaim of heat a wise economic move.

Why a HRG Series System instead of an Air to Air System?

The reclaim of heat, as developed so far, while saving heating energy, does demand the expenditure of energy in another form; fan motor horsepower to overcome the reclaim device air pressure drop. A glycol run around system requires about the same amount of extra energy to run the two fans and one pump, than an air to air system does for its two fans. However, in the glycol system, the pump may be shut off at a point when it is determined that heating savings no longer outweigh the cost for pump power.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

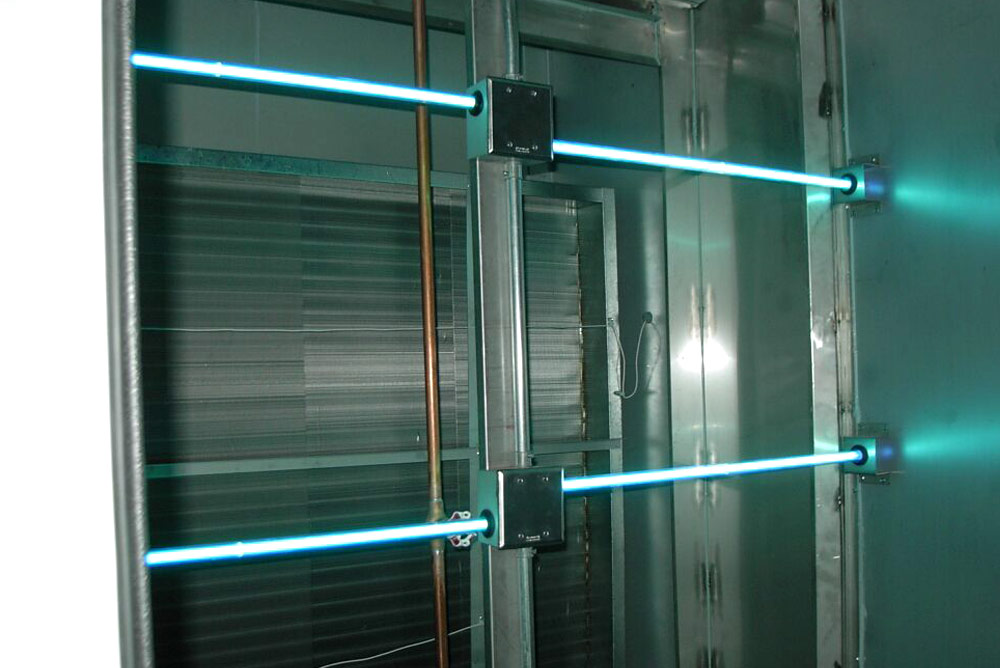

UVC Series EngA's UV Centurion Lighting System

UV-Centurion direct and indirect irradiation design provides proper UV-C ray dispersion to cover the total controlled surface, killing most common molds, bacteria and viruses in under 60 seconds.

UV-Centurion triple zone coverage separates the rain pan/lower cooling coil module from the cooling coil / filter module to irradiate the areas where molds, viruses and bacteria are most likely to collect. This combination creates system lethal to pathogens. The drain pan module with reflector , directly and indirectly cover Engineered Air's Fast Pan / drain pan system keeping them clean and free flowing. The coil face / filter module continually bathe the face of the cooling coil killing any pathogens that may be deposited there, keeping them from multiplying and eventually clogging the coil. The downstream side of the filters is also bathed continually in UV-C, killing any growth on the leaving side before it can be released downstream.

Features & Benefits

- High Output Lamps

- Quicker killing of molds, bacteria and viruses

- Total Control System

- Provides triple zone coverage

- High Polish Reflector

- Maximizes UV-C intensity and dispersion

- Pathogen Free Environment

- Reduces maintenance costs, improves running efficiencies and IAQ

- Keyed Lamp/Ballast Connector

- Ensures proper tower to each UV-C lamp

- Modular Design

- Can be installed in existing systems

- Sleeved Drain Pan Modules

- Impervious to water, controlled operating temperatures.

- Chemical Free

- No harmful effects from hazardous chemicals

- 9000 Hours Life

- Continuous cleansing of all services

UVC Series

EngA's UV Centurion Lighting System

| NAME | LETHAL DOSE (µW-sec/cm&sep2;) |

|---|---|

| Bacillus Anthracis | 4,520 |

| Corynebacterium Diptheriae | 3,370 |

| Escherichia Coli (e coli) | 3,000 |

| B. Subtilis | 7,100 |

| Micrococcus Candidas | 6,050 |

| Mycobacterium Tuberculosis | 10,000 |

| Dysentery Bacilli | 2,200 |

| Spirillum Rubrum | 4,400 |

| Streptococcus Lactis | 6,150 |

| Penicillium Expansum | 13,000 |

Features

- Control of virus, bacteria, mold and algae

- Triple zone system

- Easily serviced

- Safety Interlock

- High output lamp technology

Case Studies

-

Grant Bone and Joint Revitalization Project - Columbus, Ohio - D5582 (TC-597)

The Grant Bone and Joint Center building was originally a downtown Holiday Inn that over the years had been modified. As a former hotel the facility did not have any existing mechanical rooms and space on the roof was already limited with the existing chillers and air handling equipment.

Click to Learn More

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

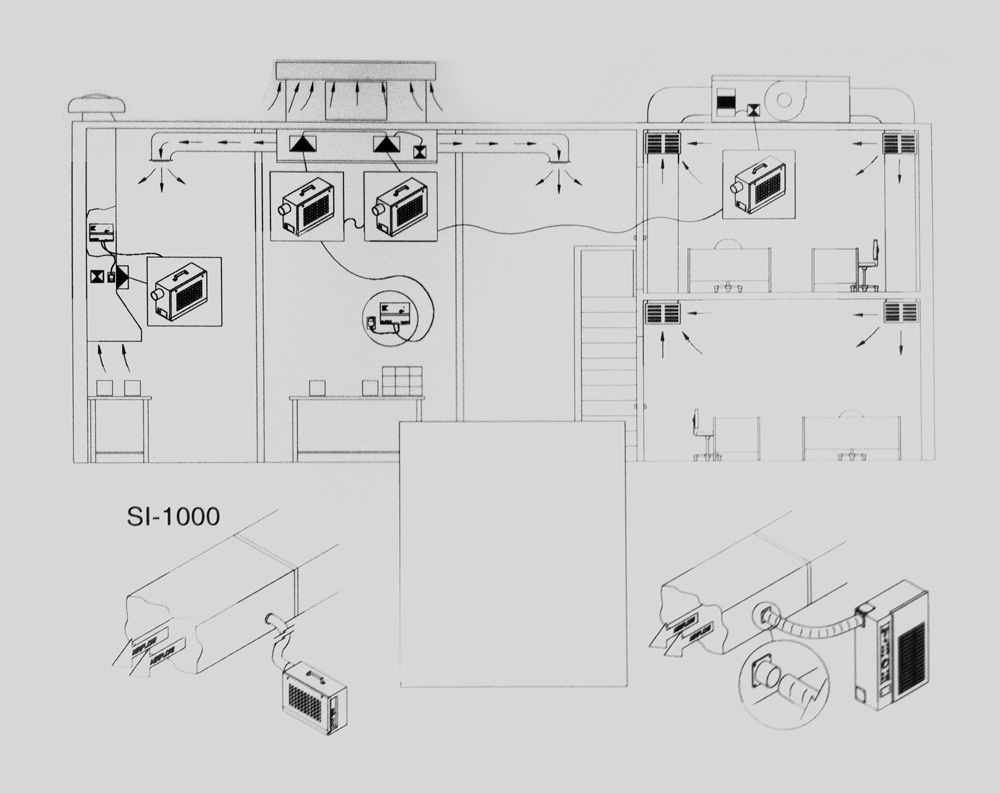

SI Series Odor Removal for Commercial and Industrial Applications

The Oxidizer process is simple. High static voltage ionizes oxygen and then using basic principles of organic chemistry it naturally breaks down (oxidizes) gaseous compounds, leaving CO2, H2O and O2 as the primary end products.

For maximum results, the Oxidizer units should be connected to the suction side of any ducted system to maximize contact time between the oxidant and odorous gases.

The Oxidizer units are easily adaptable to the A-TAC1 system to create an automated air purification system, continually balancing oxidant levels with load levels for the air.

The Oxidizer will treat air problems in spaces where there are no existing air ducts2 or can be used to inject ozone into ducted air systems.

1 A-TAC is a series of IAQ sensors for air sampling on equipment regulation

2 recommended use with A-TAC system if used in occupied space.

| Oxidizer Model |

Coverage Range of AHU by CFM |

Oxidizer Blower Size |

Mounting Weight |

Adaptable to A-TAC |

Discharge Opening |

Fan Control |

|---|---|---|---|---|---|---|

| SI-200 | 500 - 5,000 | 140 CFM | 25 lbs | yes | 3” | 0 - 100% |

| SI-500 | 1,500 - 10,000 | 140 CFM | 27 lbs | yes | 3” | 0 - 100% |

| SI-1000 | 3,500 - 25,000 | 180 CFM | 35 lbs | yes | 3” | 0 - 100% |

Features

- Forward curved blower delivers maximum air flow with high static capability

- High efficiency double screen discharge plates

- Large air inlet with 2 ply poly pad filters for maximum plate protection against particulates, extending cleaning intervals

- Variable speed fan / multi-speed fan control with hour meter

- Heavy gauge steel construction

- High output at high air volumes for maximum grams/hr rating (gm/hr)

- Easily adapted to A-TAC automatic monitoring and control system

- Safety Interlock Switch for safety during maintenance

- Large air discharge outlet for maximum grams of deliverable oxidant

- Remote mounting capabilities allows charged oxygen to be ducted into areas where there are heavy particulate loads, high humidity or other challenges while keeping the Oxidizer in a safe environment

Odorous Gases that can be Neutralized

- Formaldehyde, Xylene, Toluene, Styrene

- Glutaraldehyde, Carbon Monoxide, Acetone,

- Benzene, Hydrogen Sulfide, Ammonia, Ketone

- Complex ETS (tobacco smoke) gases and general food odors

Recommended Applications

- Paint booths, large trash bins, building exhaust systems

- Printing shops, manufacturing areas, food storage containers

- Casinos, bars, restaurants, bowling alleys, wastewater facilities

- Morgues, animal containment buildings

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

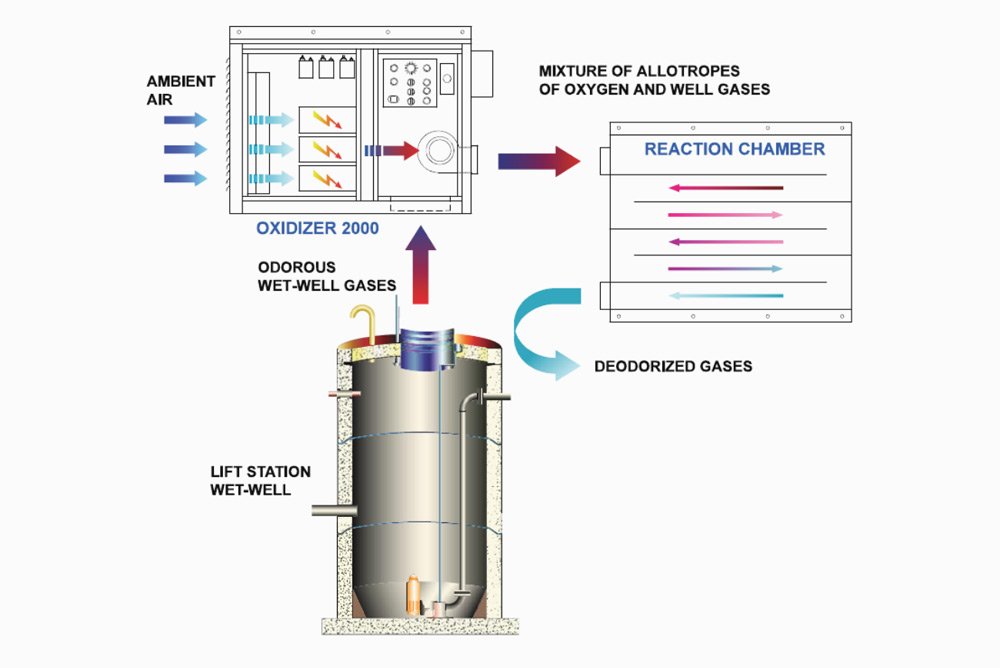

Oxidizer 2000 Odor Reduction System for Waste Water Applications

Oxidation Process

Oxidation technology can be effectively employed to break down odorous gases formed in wastewater facilities or any industrial site that causes problems for those living or working nearby. The oxidation process allows a form of oxygen (ozone) to combine with odorous molecules to break down the chemical structure and reform the atoms into simple compounds. Ozone is found naturally in the outdoors. Ozone is created by ultra violet rays from the sun or by high voltage electrical discharge during lightning storms. EngA’s Oxidizer 2000 copies nature by using high voltage to create a concentrated ozone discharge.

The TRI MED® Patented Process

The Oxidizer 2000 produces concentrated ozone within high voltage modules. A powerful fan draws the ozone from the modules combining them with the odorous gas molecules. The mixture of ozone and odorous gases is discharged into a specially designed reaction chamber. Chemical reactions take place that result in a deodorized mixture that is discharged to atmosphere. This patented process is completed with minimal operating cost, no hazardous waste to dispose of and no costly consumables to replace.

Oxidizer Features

- Corrosion resistant stainless steel enclosure

- High voltage / high output modules with removable and cleanable components

- High efficiency outside air filters

- Hinged doors for easy access to internal components

- Variable oxidation output allows easy adjustment to match applications

- Extended duct collars for easy installation

- Epoxy coated direct drive fan available in two sizes

- Motor mounted in ventilated cabinet out of air stream

- Adjustable speed controls

- 120/1/60 supply power non-fused disconnect switch

- Main control panel with NEMA 12 rated lights and switches

- Hour meter for maintenance schedule tracking

- 12 month warranty

Reaction Chamber Features

- All stainless steel construction with condensate drain

- Multi-Channel, low static, hight retention time design

- Requires no chemical additives or internal replacement media

- Extended duct collars for easy installation

- 12-month warranty

Applications

- Lift Stations, Manholes, Syphones

- Grit Rooms, Head Works, Belt Press

- Process Areas, Sludge Tanks

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

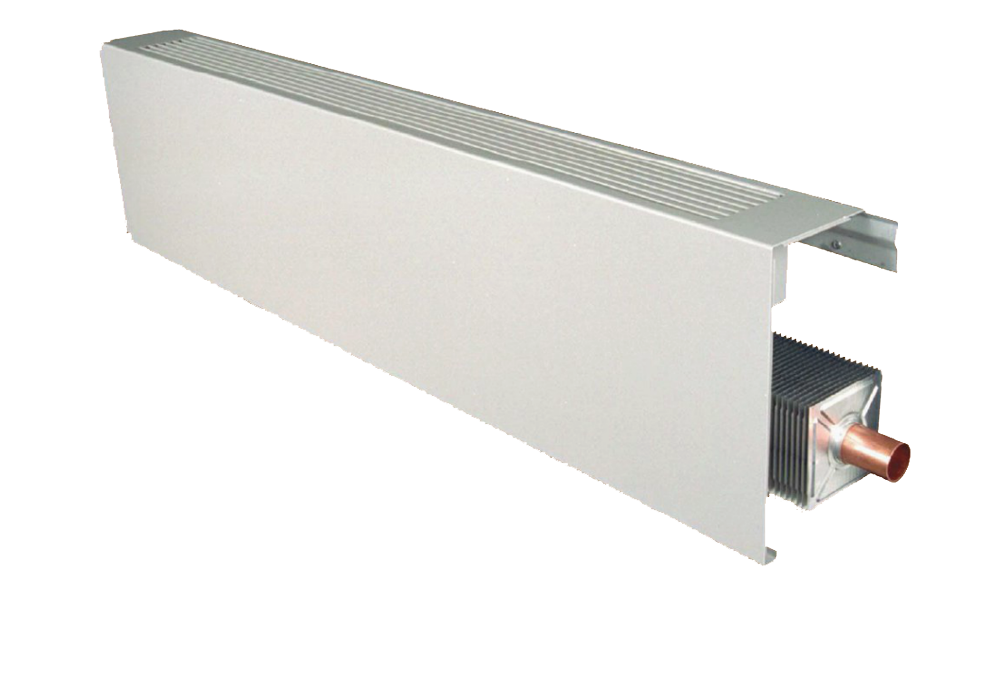

WF Series Finned Tube Radiation Solutions

Engineered Air offers either copper or steel tube element to meet you finned tube radiation requirements. Our Galvanneal steel enclosure is treated with a multi-step Oakite Cryscoat preparation before being electrostatically painted with an epoxy powder coat prime finish. You then can choose from a variety of colours at minimal additional cost for your custom baked enamel finish coat. We offer a wide variety of enclosure styles as well as custom designed enclosure.

WF Series

Finned Tubed Radiation

Enclosures

Engineered Air standard enclosures are produced in the following styles: Slope Top (WF-1), Flat Top (WF-2) and Front Outlet (WF-3). Enclosure inlets can be supplied with Open Bottom (Type A), Slope Bottom (Type B) and Front Inlet Grille (Type C). Models are available in a variety of heights from 6” (152mm) to 36” (914mm) with lengths from 2’-0” (610mm) to 6 ’-0” (1829mm) increments.

In addition to standard enclosures, Engineered Air can provide, upon request, custom designed models in a size, metal type, gauge and paint finish to suit any desired application.

Accessories

For ease of installation and design continuity, Engineered Air manufactures brackets, element hangers, joggle strips, end caps, inside and outside corners, laps, access doors, pilaster kits and manual dampers, manual dampers must be factory installed.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

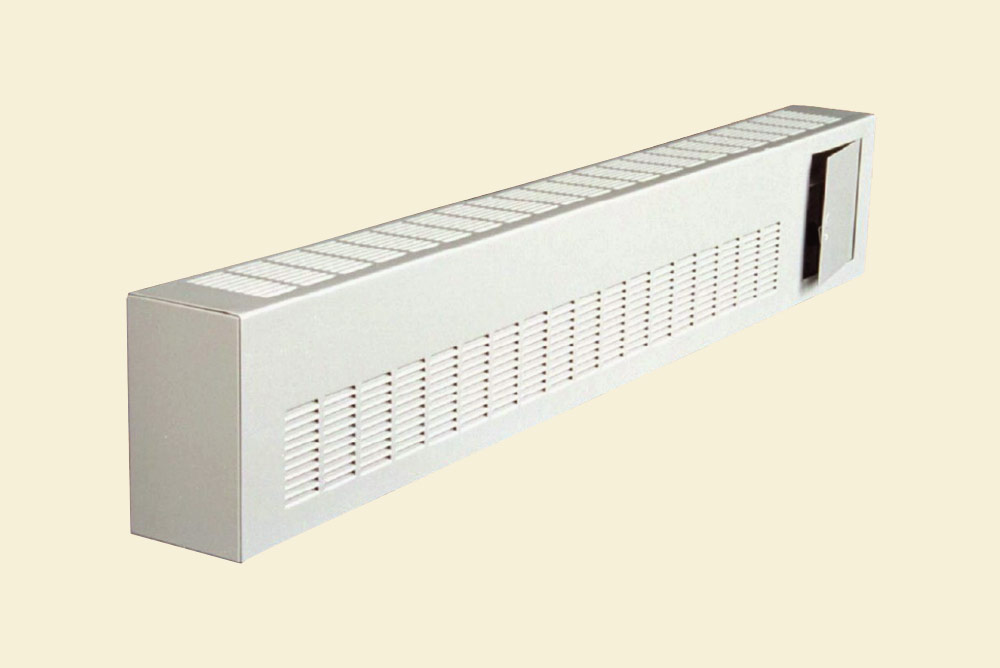

Profile Series Finned Tube Radiation Solutions

Profile Series

Finned Tubed Radiation

Enclosures

The Engineered Air Profiles Series enclosure is produced in heights of either 8” (203mm) or 10” (254mm). The Profile Series enclosure is available in lengths from 2’-0” (610mm) to 7’ - 6” (2286mm) in 6” (152mm) increments.

In addition to Profile Series enclosures, Engineered Air can provide, upon request, custom designed models in a size, metal type, gauge and paint finish to suit any desired application.

Accessories

For ease of installation and design continuity, Engineered Air manufactures brackets, element hangers, joggle strips, end caps, inside and outside corners, laps, access doors, pilaster kits and manual dampers, manual dampers must be factory installed.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

C Series Convector Radiators

C Series

Convector Radiators

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

CUH Series Cabinet Unit Heaters

CUH Series

Cabinet Unit Heaters

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

H Series Horizontal Unit Heaters

- Forestry

Pulp & Paper

Petrochemical - The Stainless Steel Horizontal and Vertical Unit Heaters meet a demand in the industry for corrosion resistant products.

- Pharmaceutical

- Built to meet the cleanliness requirements of this industry.

- Wash Facilities

- Wash areas are one of the most corrosive environments, but are often forgotten when it comes to material selection.

- Livestock / Zoos

Research - Surprisingly corrosive! Another great application for s Stainless Steel Unit Heater.

H Series

Horizontal Unit Heaters

Options

- Stainless Steel Casing

- Heresite Coated Coil

- Totally Enclosed Motor

Benefits

- Extended Life

- Corrosion Resistant

- Additional Protection

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

V Series Vertical Unit Heaters

- Forestry

Pulp & Paper

Petrochemical - The Stainless Steel Horizontal and Vertical Unit Heaters meet a demand in the industry for corrosion resistant products.

- Pharmaceutical

- Built to meet the cleanliness requirements of this industry.

- Wash Facilities

- Wash areas are one of the most corrosive environments, but are often forgotten when it comes to material selection.

- Livestock / Zoos

Research - Surprisingly corrosive! Another great application for s Stainless Steel Unit Heater.

V Series

Vertical Unit Heaters

Options

- Stainless Steel Casing

- Heresite Coated Coil

- Totally Enclosed Motor

Benefits

- Extended Life

- Corrosion Resistant

- Additional Protection

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

EngFlo Series Forced Convection Radiators

Engineered Air's rugged 16 gauge (1.5mm) construction is standard in our two units, EF-50, 50" (1270mm) and EF-100, 100" (2540mm). The EF-100 consists of (2) 50" (1270mm) covers and (1) 100" (2540mm) base unit.

Engineered Air EngFlo units can be mounted in a variety of different arrangements; wall mounted, floor mounted, ceiling hung, free standing and recessed in wall or floor. Custom configurations and materials are also available.

EngFlo Series

Forced Convection Radiators

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

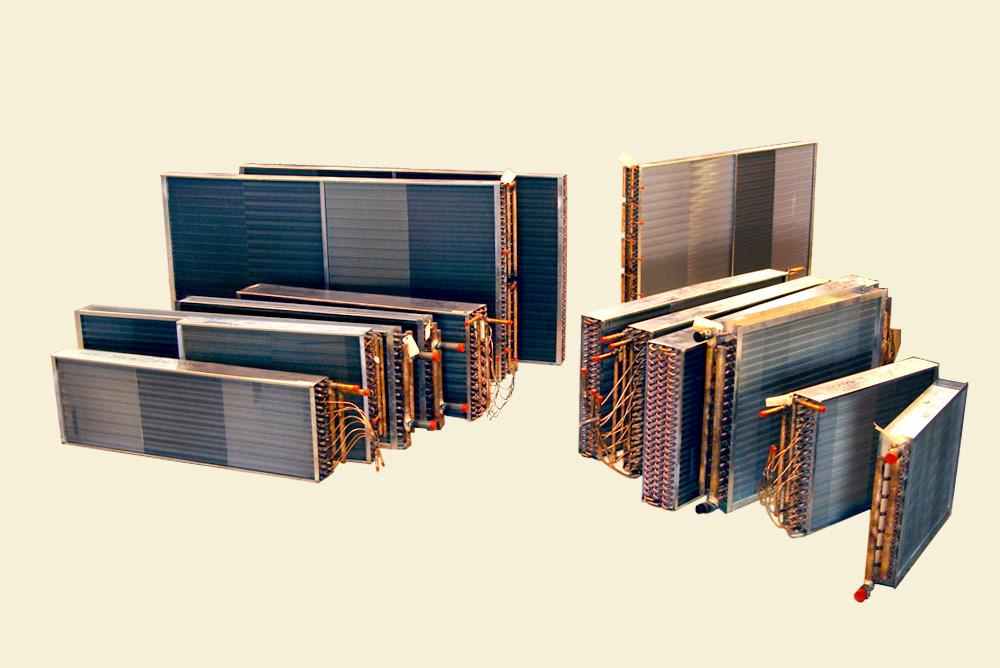

Heat Transfer Coils Commercial & Industrial Heating / Cooling Coils

Steam coils are available in standard and "steam distributing" configuration, in both 5/8" and 1" diameter tubes.

Engineered Air is proud to be able to provide replacement coils duplicating virtually any type of coil, regardless of make, age, materials, construction or dimensions. Performance is guaranteed and deliveries are fast.

Heat Transfer Coils

Wide Variety of Coils

Features

- Hot Water, Glycol, Steam Heating

- Chilled Water, Glycol, DX Cooling

- Variety of Materials and Applications

- CSA B51 Registration

Computer-aided Design

Engineered Air has developed computer programs for the selection of hot water, chilled water, steam, refrigerant and heat reclaim coils.

These advanced programs can quickly and accurately optimized coils selections by providing a choice of several coils to satisfy load requirements and system design parameters.

The broad flexibility inherent in the computer programs allows selection decisions based on initial versus operating costs.

Customer assistance is provided by a staff of trained sales people located in Engineered Air offices across Canada and the United States.

Quality Assurance

Pressure testing tanks are but one of the various inspection stages each coil undergoes prior to shipment. Visual and dimensional checks are performed during and dimensional checks are performed during assembly and upon completion to verify manufacturing accuracy.

All coils are visually checked before being subjected to a final pressure test at 300psi under water, to insure compliance with required working pressures. All resale coils bear CSA certification for Canada and the USA and catalog data provides ARI certified ratings for 5/8 water coils. Engineered Air is registered to meet the requirements of the CSA B51 Pressure Vessel Code.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

UV Series Commercial & Institutional Unit Ventilator

A Unit Ventilator for Every Application

- HUV Series

- Horizontal Multi-fan

- RUV Series

- Riser Style

- SUV Series

- Horizontal Single Fan

- VUV Series

- Vertical Floor Mounted

The VUV Series unit ventilator with its traditional arrangement is well known. Engineered Air brings a breath of fresh air to older buildings with our custom, built to fit replacement units. All models are capable of 0 to 100% outside air. The VUV is typically floor mounted on an exterior wall where fresh air is readily accessible.

The SUV Series single fan ceiling mounted unit ventilator may be just what you need. The linear arrangement could solve that tight ceiling problem. The 14 gauge fan board and full 1’ acoustic insulation, standard on all Engineered Air unit ventilators, insures quiet operation. Recessed installations have bottom access with optional hinged doors. For fully concealed SUV units, side access is recommended.

The small footprint of the RUV Series means more usable floor area. With vertical up and down flow, blow through and draw through models, Engineered Air has an arrangement for every situation. The RUV base height is adjusted to suit any floor to ceiling dimension. All Engineered Air unit ventilators features sloped stainless steel drain pans for positive condensate removal and long life. Lateral discharge ducts of rugged 16 gauge steel can be provided for down flow units. Lateral ducts have integral pencil proof louvres and are available in matching colours.

The HUV Series unit ventilator for concealed or exposed ceiling installations rounds out our family of unit ventilators. The HUV can be installed exposed (below the ceiling), flush mounted or concealed. All of our unit ventilators can be supplied with your choice of steam, water or electric heating coils and DX or water cooling coils. Duct discharge or integral grilles are available.

Engineered Air can also provide any of the models with self-contained DX cooling. This eliminates the need for outdoor condensing units that are subject to vandalism and damage. Using quiet and efficient scroll compressors provides cooling in areas that are occupied year round and allows the central plant to be shut down during idle times.

UV Series

Features

- 4 models to choose from

- Units from 600 to 2400 CFM

- Self-contained DX units available

- Custom built to specific dimensions

- Standard 16 gauge construction (14 gauge optional)

- Electrostatically applied baked polyester powder coat textured paint

- Multiple access panels

- Large piping pockets

- Allen key camlock fasteners

- Standard 14 gauge fan boards and all steel housing with galvanized steel blowers

- Optional slide out fan boards

- 1 inch 3 pound per cubic foot insulation

- Engineered Air manufactured high capacity coils

- Stainless steel drain pans with cross breaks and positive slope

- Efficient permanent split capacitor motors

- Water, Glycol, Steam, DX or Electric Coil options c/w face and bypass if desired

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

RUVG Series Institutional & Commercial Gas Fired Unit Ventilators

- Riser Style Unit Ventilator

- HIgh efficiency indirect fired heat exchanger

- Two stage heating control or modulating (optional)

- ETL Certified (Canada and USA)

RUVG Series

Institutional and Commercial Gas Fired Unit Ventilators

Features

- Heavy duty 16 gauge (1.5mm) steel cabinet.

- Durable textured powder coat finish

- 1” (25mm) acoustic insulation

- Stainless steel drain pan, sloped and insulated, c/w ⅞ (22mm) connection

- Rigid, insulated 14 gauge (1.9mm) fan board

- Large access panels with key operated cam locks & finger pull tabs

- Supply air duct collar discharge

- Mixing plenum with extrude dampers

- Quiet operating direct drive DIDW FC fans

- Multi-speed PSC motors with quick connect

- 2” (50mm) disposable filter

- High efficiency heating and cooling coils

- Wide variety of control options

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

HERESITE for Finned Tube Heating, Cooling and QDT Heat Recovery Coils

The excellent chemical and temperature resistance coupled with the good heat transfer properties of the HERESITE coating have made possible the outstanding results being obtained.

Engineered Air, in searching for corrosion resistant coating for finned tube heat transfer products, realized that HERESITE baked phenolic resins were far superior to any other type of coating on the market, both in terms of heat transfer characteristics and resistance to corrosive attach from an extremely wide range of chemicals.

HERESITE

Corrosion Protection

Description

HERESITE is the registered trademark for pure phenol-formaldehyde thermosetting resinous coatings.

The HERESITE coating applied to finned tube coils is the P-413 Flexible Brown Baking Phenolic Coating. This coating is applied to either aluminum, copper or steel with equal results.

We feel it is important to emphasize that HERESITE baking phenolic coatings are manufactured and sold only by HERESITE PROTECTIVE COATINGS INC. Further, the application of the HERESITE baking phenolic coating to finned tube coils is performed at the HERESITE plant in Manitowoc, Wisconsin, USA, at Engineered Air in Calgary, Alberta, Canada and at other authorized facilities.

Advantages

Practically all typed of finned tube coils used for oil, water, air, gas and process cooling (and heating) as well as a large condensing coils can be HERESITE protected against damaging environments. Currently, the HERESITE coating of air-conditioning and industrial process coils exposed to corrosive fumes and salt atmosphere is in the increase, with many new applications being found.

HERESITE coating offers a more economical solution that special metals for these applications. Typically, aluminum fin coil coated with HERESITE are more economical than copper fin coils. Special metal casing materials are unnecessary since the HERESITE coating is applied to the casing as well as to the finned tubes. Additionally, HERESITE coated aluminum fins will resist attack from most cleaning agents more successfully than copper fin coils.

Application

The present day HERESITE coating of finned tube coils is the result of many years experience during which time application equipment and procedures have been constantly improved. Today, Engineered Air has one of the largest HERESITE facilities in the world. The enables us to HERESITE coat, on a routine basis, coils up to the following size and weight:

- Maximum Fin Dimensions

- 240” long × 78” wide × 18” deep

- Maximum Weight Per Coil

- 4,000 pounds per coil

- Fin Spacing, 1 to 3 tube rows

- 16 per inch maximum

- Fin Spacing, 4 to 6 tube rows

- 14 per inch maximum

- Fin Spacing, 7 and 8 tube rows

- 12 per inch maximum

The HERESITE coating of finned tube coils is accomplished by a multiple coat application of dipping and baking resulting in complete coating coverage of the fins, tubes, headers, casings, etc. Consequently, protection against corrosion is provided for the entire coil. Due to specialized surface preparation techniques plus the good adhesive properties of the HERESITE P-413 coating, it is possible to efficiently HERESITE coat all the usual metals used in fabricating finned tube coils.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

LAMIFLO Series Integral Face & Bypass Coils

Full flow is sent through the coil at all times, preventing freezeup. Temperature control is maintained by a series of Face and Bypass Dampers, spaced evenly over the face of the LAMIFLO. Face dampers are employed on both the entering and eliminate unwated heat pickup.

The use of LAMIFLO Face and Bypass Dampers for makeup air applications has a very distinct advantage over valve control. A coil is selected for the very worst condition possible - and then often oversized. When the outdoor air temperature is much warmer than the design point, but still below freezing, a control valve is often oscillating between cracked open and fully closed. In one of those fully closed moments, it doesn't take long to chill and then freeze the stationary fluid in the tubes.

With LAMIFLO Face and Bypass Dampers, the steam or fluid flow is constant during the period that the outdoor air temperature is below freezing. Temperature control is achieved by metering the incoming cold air through multiple narrow heating and bypass channels to mix at the control temperature. The bypass channels have been sized to provide a pressure drop when fully open that is equal to the pressure drop through the coil, or heating channel when fully open, to assure a constant volume of air. The air streams emerging from the narrow channels are LAMINATED and mixing is virtually complete within 36” (0.9m) of the LAMIFLO section.

The advantage of LAMIFLO over conventional internal or external face and bypass dampers is clean; the homogenous air temperature mix is far superior, and downstream devices, for example, reheat coils, cooling coils, or humidifiers, need not be spaced a great distance from the LAMIFLO section to retain even velocity loading. Air pressure drop is minimal on LAMIFLO coils. Conventional bypass dampers, with all the bypass air passing over top of the heating coil, create a system effect that demands extra horsepower.

LAMIFLO Series

Features

- Uniform heat for makeup air applications

- Steam, hot water or glycol

- Minimizes temperature swing

- Eliminates stratification

- Vertical and horizontal configurations

- Installation in ductwork or Engineered Air units

| Features | Benefits |

|---|---|

| Integral heating coil and bypass sections | Provides safe, even heat for make up air applications |

| Two sets of face dampers (upstream & downstream) | Eliminates coil “wiping”. Mixing is virtually complete within 36” (914mm) |

| Balanced pressure drops in coil and bypass sections | Provides constant air flow at each extreme of operation |

| Coil sections designed for full flow of steam, water or glycol | Maximizes freeze protection |

| Horizontal or Vertical configuration | Accommodates steam, hot water or glycol as well as piping considerations |

| Heavy duty construction | Suitable for commercial and industrial applications |

| Factory assembled and pressure tested. Dampers are set and welded | Assures trouble free operation |

| Optional CSA B51 pressure vessel code certification and construction for resale coils | Accommodates high pressure steam, hot water and glycol applications with copper or steel tubes |

| Optional in house HERESITE coated coils | Provides effective resistance to corrosion of fins, tubes and headers |

| ARI certified ratings of ⅝” water coils | Assures performance based on certified catalog data |

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

AIRTEX Radiant Ceiling Systems - The New Standard in Perimeter Heating

The Airtex extruded aluminum panels in lengths up to 16' (4877mm) have changed the way North America heats its buildings. Clean durable Airtex Radiant Linear products are great for the hospital, school, laboratory and office.

A continuous architectural perimeter band constructed to virtually any panel width from interlocking extrusions.

An innovative mechanical bonding technique maximizes heat transfer between copper circulating coils and aluminum extrusions.

AIRTEX MODULAR PANELS

Airtex Modular Radiant Panels fit in standard acoustic ceiling tile grids and can be placed almost anywhere a regular ceiling tile might go.

An efficient, patented metallurgical bonding technique between copper coil and aluminum sheet.

Panel face can be custom coloured or silk-screened to match acoustic ceiling tile.

AIRTEX Radiant Panels

Radiant Ceiling Systems - The New Standard in Perimeter Heating

Major Applications

-

Educational Facilities

Durable and efficient AIRTEX Panels provide the necessary wall space, occupant comfort and freedom of maintenance desired in al schools.

-

Hospitals

AIRTEX Systems provide ultimate patient comfort in an aseptic environment, with no maintenance.

-

Office Buildings

AIRTEX Systems meet architectural criteria for aesthetics, energy and space efficiency plus easy tenant flexibility.

-

Airports

AIRTEX Systems provide a clean, draftless, uniform environment with unlimited use of perimeter space.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

AF Series Air Cooled Condensers

The Condenser coil is of copper tube / aluminum fin construction as standard although other materials are available as an option. Custom circuiting is utilized to provide optimum capacity with minimum pressure drop.

Proven components, which have withstood the rigorous test of time, are used in the air moving assemblies. Venturi openings are spun to exacting tolerance to insure maximum airflow with minimum horsepower requirements.

All electrical components (standard or optional) are of the highest quality.

AF Series

Air Cooled Condensers

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

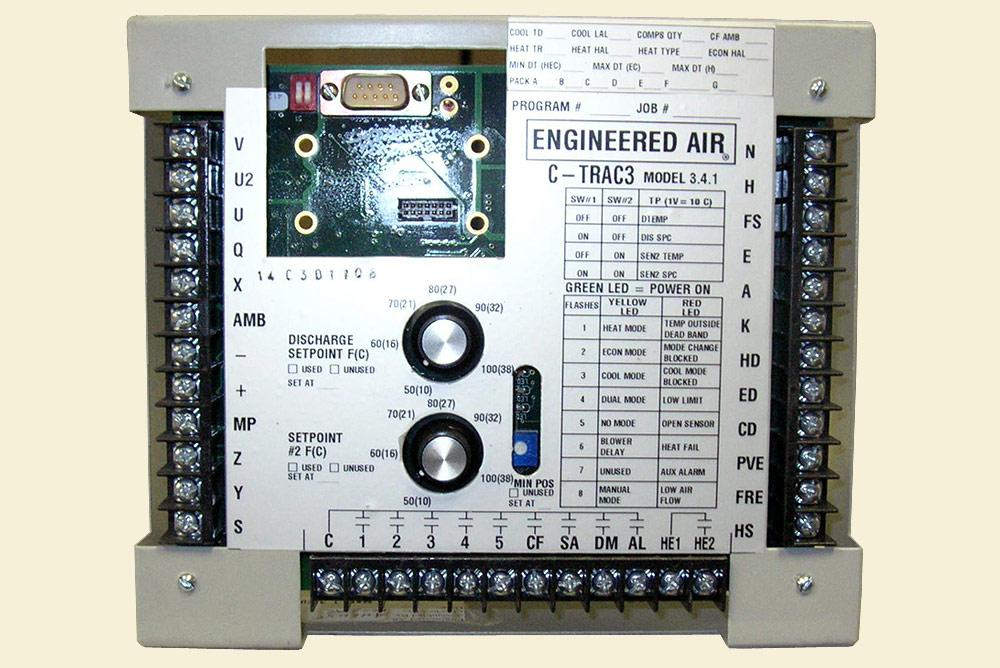

C-TRAC Cooling Sequencer

It is the highest level of the TRAC Family. Other Engineered Air TRAC controllers can be slaved to the C-TRAC. The slaved heating controller receives a 0-10VDC control signal from the C-TRAC.

C-TRAC

Cooling Sequencer

The TRAC family of product specific controls have been designed:

- To provide precise control, white also incorporating operating and safety limits

- To eliminate electro-mechanical devices, (switches, relays, etc) by means of logic based programming.

- To provide rugged, dependable controllers than can withstand the rigors of a rooftop installation. The ability to operate at -40°F ambient and in the presence of electronic noise are essential

Technical Data | |

|---|---|

Power Supply: 24 VAC - 10VA Contact Rating: 70VA @ 24VAC, 360VA @ 120VAC Inrush Rating: 1800VA |

|

| Digital Inputs (DI): 3 | Digital Outputs (DO): 5 |

|

|

| Analog Inputs (AI): 4 | Analog Outputs (AO): 2 |

|

|

| Ambient Operating Temperature Limits | Temperature Sensors |

Maximum: 105°F ( 40°C ) Minimum: -40°F ( -40°C ) |

1000 ohm Thin Platinum Positive Temperature Coefficient Devices (PTC) |

| Economizer Minimum Position | Dead Band |

0 - 100% |

Fully adjustable 5°F to 12°F |

| Timing Functions | Control Algorithms |

|

|

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

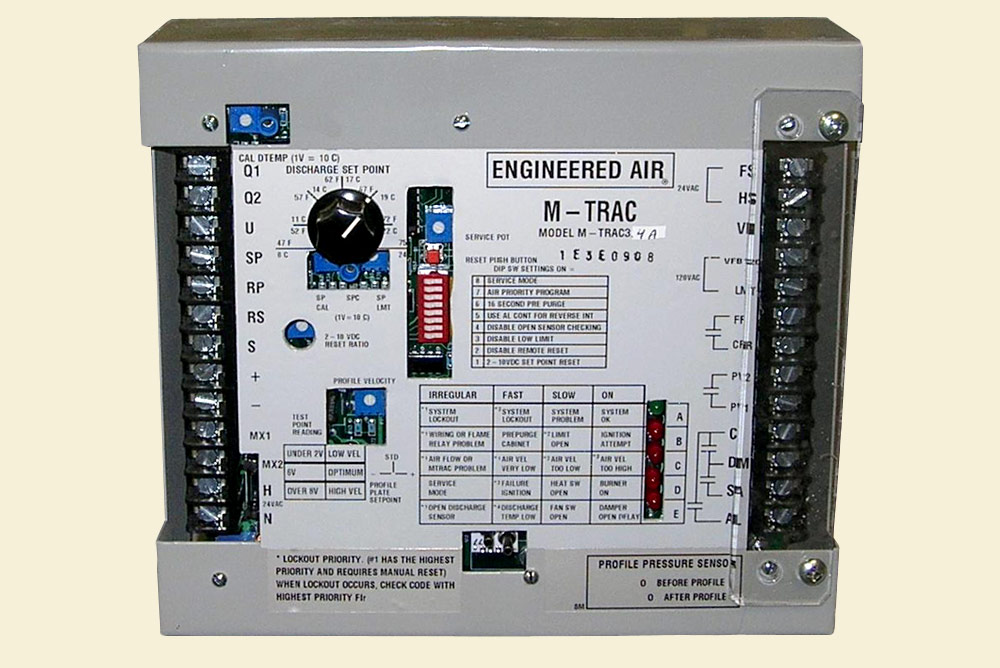

G-TRAC Industrial Gas Heater Controller

Together the DG high turndown burner and the G-TRAC controller provide optimum air heater performance.

The G-TRAC is a stand-alone controller for the Engineered Air series DG Industrial Furnance. Alternatively it can be slaved from the C-TRAC Cooling Sequencer for integrated control of a packaged air conditioner, such as the Engineered Air FW-DG, or a split system using a DG heat section and a CU condensing unit.

G-TRAC

Industrial Gas Heater Controller

Technical Data | |

|---|---|

Power Supply: 24 VAC Contact Rating: 70VA @ 24VAC, 360VA @ 120VAC Inrush Rating: 1800VA |

|

| Digital Inputs (DI): 4 | Digital Outputs (DO): 8 |

|

|

| Analog Inputs (AI): 6 | Status Indication: |

|

4 LED's on face of panel provide status information including the following:

|

| Ambient Operating Temperature Limits | Temperature Sensors |

Maximum: 105°F ( 40°C ) Minimum: -40°F ( -40°C ) |

1000 ohm Thin Film Platinum Positive Temperature Coefficient Device (PTC) |

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

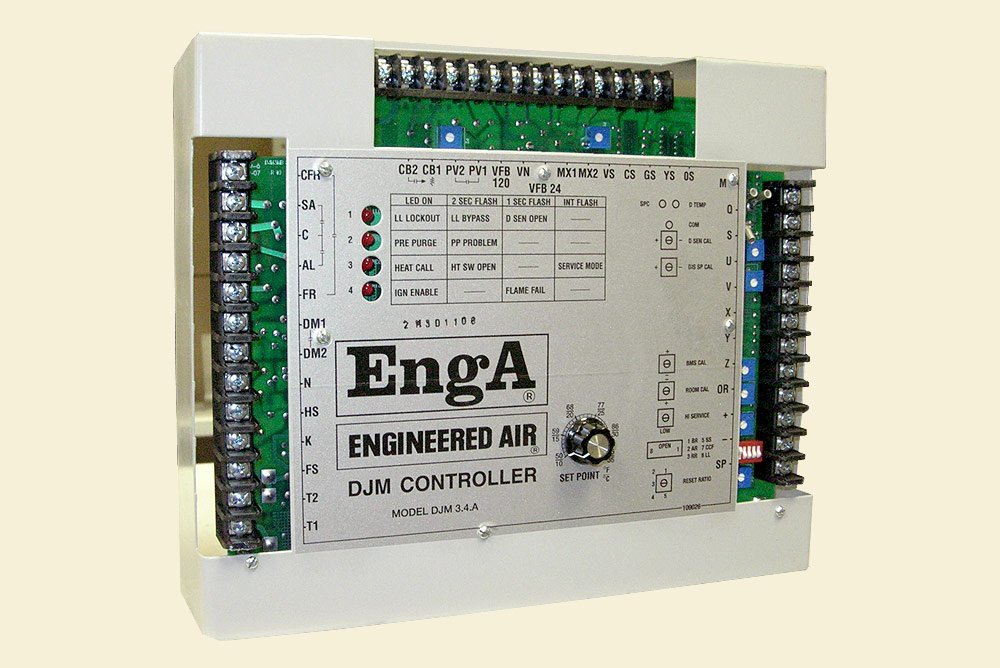

DJM Controller

The DJM controller is a programmed logic device that provides proportional-integral control when used with any one of the DJ series burners. The basic function of the DJM is to control discharge air temperature. The discharge air setpoint can be set either at a fixed value, or can be reset from a number of options.

The DJM in its various forms can operate as either a stand-alone controller, or it can be interfaced with our C-TRAC mechanical cooling controller.

DJM Series

Controller

Technical Data | |

|---|---|

Power Supply: 24 VAC Contact Rating: 70VA @ 24VAC, 360VA @ 120VAC Current Draw: 1.2 amps |

|

| Digital Inputs (DI): 4 | Digital Outputs (DO): 5 |

|

|

| Analog Inputs (AI): 6 | Analog Outputs (AO): 2 |

|

|

| Status Indication | Ambient Operating Temperature Limits |

4 LED's on face of panel.

|

Maximum: 105°F ( 40°C ) Minimum: -40°F ( -40°C ) |

| Temperature Sensors | |

| 1000 ohm thin film platinum Positive Temperature Coefficient Device (PTC) | |

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

H-TRAC Heat Sequencer

The electric heat coil controlled by an H-TRAC controller is specifically designed with stages sized for operation with the binary control logic. Stage one is smallest, stage two is double stage one, and stages three, four and five are each four times the output of stage one. In this manner by activating various combinations of the physical stages, fifteen "equivalent" control stages are created (7 or 11 equivalent stages can also be provided.)

The H-TRAC can be used in a variety of control applications. Avaliable options are:

- Discharge air control with 135 Ω proportional controller

- Discharge air control with Maxitrol electronic sensor and setpoint adjustment

- Room control with modulating high and low limits

- 0-10VDC or 4-20MA reset of discharge air setpoint

- Direct control from a higher level controller (i.e. H-TRAC becomes a slaved controller)

H-TRAC

Heat Sequencer

Technical Data | |

|---|---|

Power Supply: 24 VAC Current Draw: 6VA Contact Rating: 70VA @ 24VAC, 360VA @ 120VAC Inrush Rating: 1800VA |

|

| Digital Inputs (DI): 0 | Digital Outputs (DO): 5 |

| None. |

|

| Analog Inputs (AI): 4 | Analog Outputs (AO): 0 |

|

None. |

| Status Indication | Ambient Operating Temperature Limits |

One LED behind panel. |

Maximum: 105°F ( 40°C ) Minimum: -40°F ( -40°C ) |

View Brochure PDF Request Access to our Complete Catalog