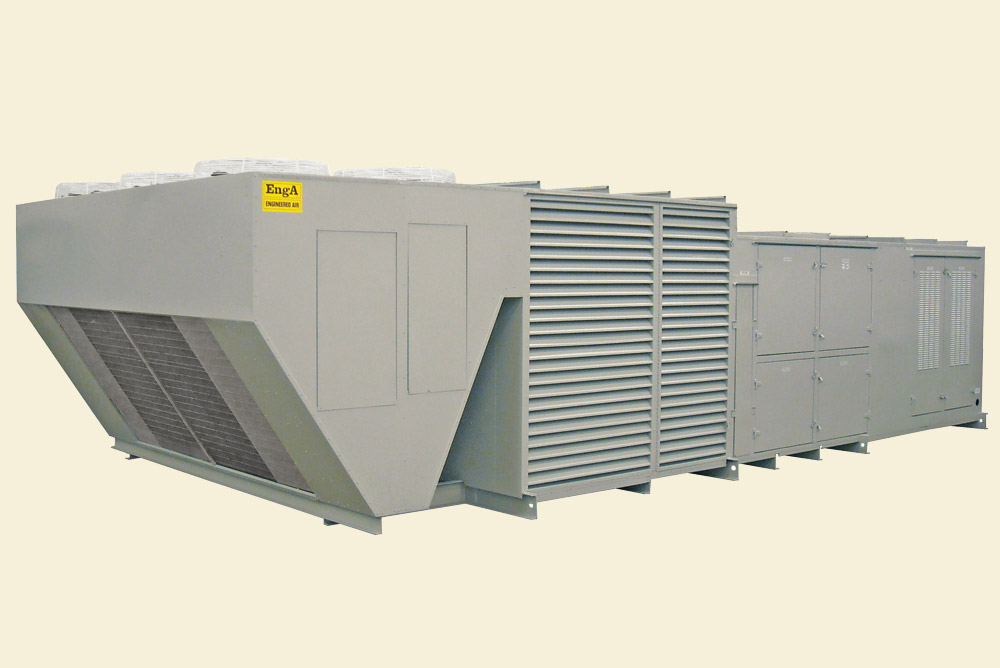

FWE Series Commercial & Industrial Mechanical Cooling / Heating Units

Standard configuration for an FWE series product includes forward curved fans but can be modified to include Backward Inclined fans, Airfoil fans, Plenum fans, etc...

FWE Series

Commercial & Industrial Mechanical Cooling / Heating Units

Features

- Multiple staged compressors and / or modulating compressor

- Energy efficiency verified models available

- R-407C, R-410A and optional R-134a refrigerants

- Direct or indirect gas-fired heaters (high efficiencies and turndowns)

- Hydronic and electric heating coils

- Total or sensible energy recovery components

- Custom fans - EngArray

- Your equipment solution for sustainable buildings

- 6 through 120 tons of mechanical cooling

- 1,600 to 56,000 CFM air volumes

- Custom units for non-catalogued capacities

- Multiple independent compressor circuits

- Dedicated EngA TRAC Controllers

- Unit base fabricated from steel channel

Typical Options ( * ) represents standards features

Case Studies

-

Grant Bone and Joint Revitalization Project - Columbus, Ohio - D5582 (TC-597)

The Grant Bone and Joint Center building was originally a downtown Holiday Inn that over the years had been modified. As a former hotel the facility did not have any existing mechanical rooms and space on the roof was already limited with the existing chillers and air handling equipment.

Click to Learn More

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

UPEW Series Water Cooled Packaged Air Conditioners

The UPEW Series lend themselves to small office buildings, commercial retail space and food service areas where the use of air-cooled equipment is not feasible. Water-cooled air conditioners provide significantly higher Energy Efficiency Ratios (EER).

Features

- Pre-wired, water cooled packaged air conditioners

- single & multiple quiet running gas cooled hermetic scroll type compressors

- Resiliently mounted forward curved supply air blowers

- Tube-in-tube refrigerant condensers

- Sound treated compressor-condenser compartment

- Two inch deep MERV 7 pleated filters

- Vertical or horizontal (back or front) fan discharge

Available Options

- Air Handler

- Airfoil fans (DIDW or SISW), plenum fans

- Compressors

- Hermetic reciprocating

- Condensers

- Cleanable shell and tube type, brazed plate stainless steel

- Evaporators

- Alternate tube circuiting

- Filters

- Cartridges, bags, HEPA and chemical types

- Free Coolers

- At lower outdoor temperatures, a separate hydronic coil to use with cooling towers

- Glycol Condensing Circuits

- Selections available

- Heating Coils

- Hydronic or electric

- Variable Air Volume

- Variable speed drives, inlet vanes

- Silencers

- Integral return air silencers, add-on supply air silencers

- Sound Treated Casings

- Extra heavy wall, 3-lb/ft3 rigid insulation, 24 ga. perforated liner

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

FW/HE Series Mechanical Cooling / Direct Fired Makeup Air Units

FWE/HE units are available with side, up, or down discharge. Roof curbs are available where required.

FW / HE Unit

Direct Fired Makeup Air with Mechanical Cooling

Features

- Energy efficiency verified models available

- R-470C, R-410A and R-134a refrigerants

- Multiple independent compressor circuits

- Custom units for non-catalogued capacities

- Dedicated Engineered Air TRAC controllers

- EER ratings meet of exceed ASHRAE 90.1 requirements

- High efficiency Green Burn burner

- Packaged direct fired burner with mechanical cooling

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

FW/DJ Series Mechanical Cooling / Indirect Fired Makeup Air Units

FW/DJ units are available with side, up or down discharge. Roof curbs are available where required.

FW / DJ Unit

Mechanical Cooling / Indirect Fired Makeup Air Unit

Features

- Energy efficiency verified models available

- R-407C, R-410A and R-134a refrigerants

- Multiple independent compressor circuits

- Custom units for non-catalogued capacities

- Dedicated Engineered Air TRAC controllers

- EER ratings meet or exceed ASHRAE 90.1 requirements

- Indirect gas fired heat exchanger capable of 100% makeup air

- Packaged indirect fired burner with mechanical cooling

Typical Options ( * ) represents standards features

Applications

The FW/DJ Series is excellent in providing makeup air for hallway pressurization, industrial facilities, food processing, commercial kitchens, health care, laboratories, athletic facilities or anywhere there is a need to heat and cool 100% outdoor air.

Components

- Burner / Blower

- Refer to DJ Series Indirect Fired Heaters.

- Compressor

- Available in multiple hermetic scroll or reciprocating models that are similar to the FW Series cooling units.

- Evaporator

- Alternate tube coil that is individually selected to meet specific conditions of operation.

- Controls

- Refer to the Control Section or contact your Engineered Air Sales Representative

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

CU Series Air Cooled Condensing Units

CU Series

Air Cooled Condensing Unit

Features

- Multiple staged compressors and / or modulating compressor

- Energy efficiency verified models available

- R-407C, R-410A and optional R-134a refrigerants

- Single circuited hermetic scroll compressors

- Tandem circuited hermetic scroll compressors available

- Your equipment solution for sustainable buildings

- 3 to 120 ton units

- Custom units for non-catalogued capacities

- Multiple independent compressor circuits

- Indoor and outdoor configurations

- Unit base fabricated from steel channel

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

FW/EC Series Packaged Air Conditioners with Evaporative Condensers

The FW/EC series of air conditioners utilizes the benefits of evaporative cooling in the condenser, allowing condensing temperatures in the range of 100°F to 110°F, even with ambient dry bulb temperatures at 100°F or over, as long as the web bulb temperature of the outside air is at 80°F or lower.

Features

- Meets or exceeds ASHRAE 90.1 efficiencies

- Supply air temperatures as low as 44°F

- Walk-in compressor section

- Excellent serviceability

- Full range of heating accessories

- Full range of filtration accessories

- Minimized unit footprint

Applications

Lower condensing temperatures with the resulting higher EER's mean lower operating costs for the owner. Even when operating cost is not a concern, (seldom the case), building code authorities may impose electrical energy input limits on the air conditioning system, most often along the lines laid out in the ASHRAE Standard 90.1.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

MZ Series Commercial - Industrial Heating and Cooling

Reduced energy consumption through:

- up to 15:1 turndown with gas heat

- multiple compressors

- improved control systems

MZ Series

Commercial - Industrial Heating and Cooling

Features

- Hot Deck available with Gas, Hydronic or Electric heat

- Wide range of gas fired heating capacities

- Available with DX or chilled water cooling

- Multiple Compressors

- Independently piped and circuited compressors

- Hot gas bypass on lead compressor

- 15:1 turndown on indirect gas fired hot deck

- Hot deck temperature inversely reset from outdoor ambient

- Z bar Roof Curb mating flanges

- Interface with BMS (Build Management Systems) or existing 135 OHM room thermostats

- Parallel flow hot / cold decks

- Blow through cold deck

- Hinged front access on unit discharge

- Integrating increased cooling capacity on existing roof curbs

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

MC Series Commerical & Industrial Water or Air Cooled Modular Chillers

The principle of modular chiller design is that a smaller individual chiller (a module) can be connected with other modules to create a larger cooling system, either initially or over time. Sections of 6" (152mm) diameter pipe connected with Victaulic couplings are used to form a common header. This allows the common header to be pre-shipped to the job site and piped into the building piping system before the rest of the equipment arrives.

MC Series Modular Chillers

Commerical & Industrial Water or Air Cooled Modular Chillers

Features / Options

- Single stand alone chillers or up to 12 units in a modular configuration

- Energy efficiency verified models

- Service any module while the rest of the system continues to cool

- Display showing descriptive system information on each module

- Controller automatically removes serviced unit

- Victaulic water-header connections

- Easy acces to major components

- Fits through 28

- Simple system expansion

- Match capacity at any load with multiple units

- Master controller for control of modular configurations

- Packaged or remote air cooled condensers

Typical Options ( * ) represents standards features

Typical Options (*) represents standard features

| Casing / Finishes | Cooling | Water Side | Controls |

|---|---|---|---|

|

|

|

|

Benefits

Expandability

Allows the system to grow with the cooling load. Modules can be added at a future date without doing any piping work.

Better Capacity Control Each individual circuit is operating at its optimum efficiency point, providing a high operating efficiency even though the overall assembly is operating at partial load.

Installation

Units are connected to the header using isolation valves and flex joints, meaning they can be mounted directly onto a concrete slab. Header sections are identical to one another. They can be pre-shipped ahead of the chillers, allowing the building piping system to be pre-built.

Flexible Installation Arrangements

The external common header means that modules can be located in different parts of the room or even in separate rooms. As long as the piping is connected so that the master controller measures the system fluid temperature, the system will work effectively.

Service While Under Full Operation

Designed to allow service to all the liquid line components on any of the chillers while the system is under operation.

Redundancy

Add one more module to the system for an "N + 1" capacity so that the overall cooling system capacity is not affected when a module is taken out for regular service or needs repair. Each unit has two independent circuits. If one is lost, only that circuit is affected while all others remain operational. Each module has a fully functioning dedicated logic controller. If communication is lost with the master controller, the individual controllers will automatically take over control of each module. By presetting and staging the set points on all the local controllers, they will then control the system.

Front Serviceability

Set up so that it is front serviceable making it easy to access components requiring routine maintenance.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.