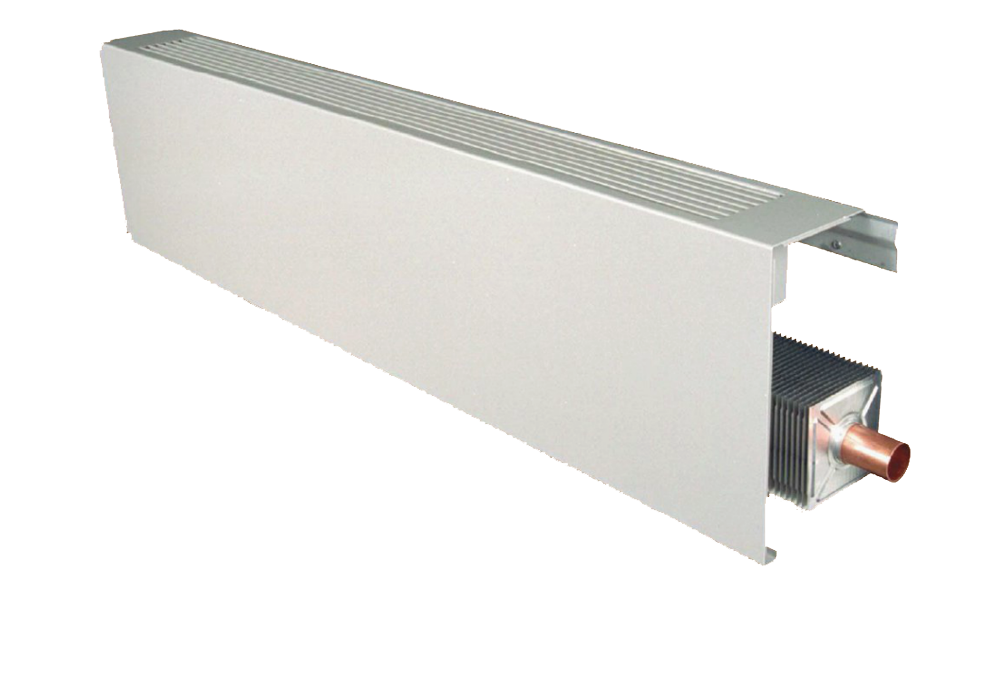

WF Series Finned Tube Radiation Solutions

Engineered Air offers either copper or steel tube element to meet you finned tube radiation requirements. Our Galvanneal steel enclosure is treated with a multi-step Oakite Cryscoat preparation before being electrostatically painted with an epoxy powder coat prime finish. You then can choose from a variety of colours at minimal additional cost for your custom baked enamel finish coat. We offer a wide variety of enclosure styles as well as custom designed enclosure.

WF Series

Finned Tubed Radiation

Enclosures

Engineered Air standard enclosures are produced in the following styles: Slope Top (WF-1), Flat Top (WF-2) and Front Outlet (WF-3). Enclosure inlets can be supplied with Open Bottom (Type A), Slope Bottom (Type B) and Front Inlet Grille (Type C). Models are available in a variety of heights from 6” (152mm) to 36” (914mm) with lengths from 2’-0” (610mm) to 6 ’-0” (1829mm) increments.

In addition to standard enclosures, Engineered Air can provide, upon request, custom designed models in a size, metal type, gauge and paint finish to suit any desired application.

Accessories

For ease of installation and design continuity, Engineered Air manufactures brackets, element hangers, joggle strips, end caps, inside and outside corners, laps, access doors, pilaster kits and manual dampers, manual dampers must be factory installed.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

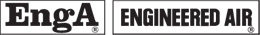

Profile Series Finned Tube Radiation Solutions

Profile Series

Finned Tubed Radiation

Enclosures

The Engineered Air Profiles Series enclosure is produced in heights of either 8” (203mm) or 10” (254mm). The Profile Series enclosure is available in lengths from 2’-0” (610mm) to 7’ - 6” (2286mm) in 6” (152mm) increments.

In addition to Profile Series enclosures, Engineered Air can provide, upon request, custom designed models in a size, metal type, gauge and paint finish to suit any desired application.

Accessories

For ease of installation and design continuity, Engineered Air manufactures brackets, element hangers, joggle strips, end caps, inside and outside corners, laps, access doors, pilaster kits and manual dampers, manual dampers must be factory installed.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

C Series Convector Radiators

C Series

Convector Radiators

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

CUH Series Cabinet Unit Heaters

CUH Series

Cabinet Unit Heaters

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

H Series Horizontal Unit Heaters

- Forestry

Pulp & Paper

Petrochemical - The Stainless Steel Horizontal and Vertical Unit Heaters meet a demand in the industry for corrosion resistant products.

- Pharmaceutical

- Built to meet the cleanliness requirements of this industry.

- Wash Facilities

- Wash areas are one of the most corrosive environments, but are often forgotten when it comes to material selection.

- Livestock / Zoos

Research - Surprisingly corrosive! Another great application for s Stainless Steel Unit Heater.

H Series

Horizontal Unit Heaters

Options

- Stainless Steel Casing

- Heresite Coated Coil

- Totally Enclosed Motor

Benefits

- Extended Life

- Corrosion Resistant

- Additional Protection

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

V Series Vertical Unit Heaters

- Forestry

Pulp & Paper

Petrochemical - The Stainless Steel Horizontal and Vertical Unit Heaters meet a demand in the industry for corrosion resistant products.

- Pharmaceutical

- Built to meet the cleanliness requirements of this industry.

- Wash Facilities

- Wash areas are one of the most corrosive environments, but are often forgotten when it comes to material selection.

- Livestock / Zoos

Research - Surprisingly corrosive! Another great application for s Stainless Steel Unit Heater.

V Series

Vertical Unit Heaters

Options

- Stainless Steel Casing

- Heresite Coated Coil

- Totally Enclosed Motor

Benefits

- Extended Life

- Corrosion Resistant

- Additional Protection

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

EngFlo Series Forced Convection Radiators

Engineered Air's rugged 16 gauge (1.5mm) construction is standard in our two units, EF-50, 50" (1270mm) and EF-100, 100" (2540mm). The EF-100 consists of (2) 50" (1270mm) covers and (1) 100" (2540mm) base unit.

Engineered Air EngFlo units can be mounted in a variety of different arrangements; wall mounted, floor mounted, ceiling hung, free standing and recessed in wall or floor. Custom configurations and materials are also available.

EngFlo Series

Forced Convection Radiators

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

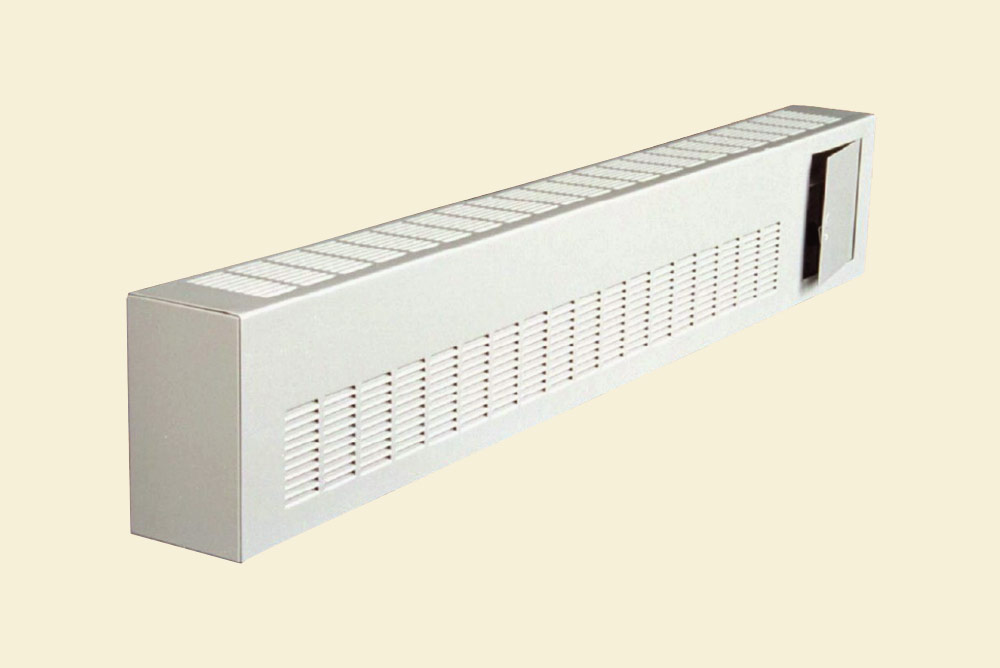

Heat Transfer Coils Commercial & Industrial Heating / Cooling Coils

Steam coils are available in standard and "steam distributing" configuration, in both 5/8" and 1" diameter tubes.

Engineered Air is proud to be able to provide replacement coils duplicating virtually any type of coil, regardless of make, age, materials, construction or dimensions. Performance is guaranteed and deliveries are fast.

Heat Transfer Coils

Wide Variety of Coils

Features

- Hot Water, Glycol, Steam Heating

- Chilled Water, Glycol, DX Cooling

- Variety of Materials and Applications

- CSA B51 Registration

Computer-aided Design

Engineered Air has developed computer programs for the selection of hot water, chilled water, steam, refrigerant and heat reclaim coils.

These advanced programs can quickly and accurately optimized coils selections by providing a choice of several coils to satisfy load requirements and system design parameters.

The broad flexibility inherent in the computer programs allows selection decisions based on initial versus operating costs.

Customer assistance is provided by a staff of trained sales people located in Engineered Air offices across Canada and the United States.

Quality Assurance

Pressure testing tanks are but one of the various inspection stages each coil undergoes prior to shipment. Visual and dimensional checks are performed during and dimensional checks are performed during assembly and upon completion to verify manufacturing accuracy.

All coils are visually checked before being subjected to a final pressure test at 300psi under water, to insure compliance with required working pressures. All resale coils bear CSA certification for Canada and the USA and catalog data provides ARI certified ratings for 5/8 water coils. Engineered Air is registered to meet the requirements of the CSA B51 Pressure Vessel Code.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

UV Series Commercial & Institutional Unit Ventilator

A Unit Ventilator for Every Application

- HUV Series

- Horizontal Multi-fan

- RUV Series

- Riser Style

- SUV Series

- Horizontal Single Fan

- VUV Series

- Vertical Floor Mounted

The VUV Series unit ventilator with its traditional arrangement is well known. Engineered Air brings a breath of fresh air to older buildings with our custom, built to fit replacement units. All models are capable of 0 to 100% outside air. The VUV is typically floor mounted on an exterior wall where fresh air is readily accessible.

The SUV Series single fan ceiling mounted unit ventilator may be just what you need. The linear arrangement could solve that tight ceiling problem. The 14 gauge fan board and full 1’ acoustic insulation, standard on all Engineered Air unit ventilators, insures quiet operation. Recessed installations have bottom access with optional hinged doors. For fully concealed SUV units, side access is recommended.

The small footprint of the RUV Series means more usable floor area. With vertical up and down flow, blow through and draw through models, Engineered Air has an arrangement for every situation. The RUV base height is adjusted to suit any floor to ceiling dimension. All Engineered Air unit ventilators features sloped stainless steel drain pans for positive condensate removal and long life. Lateral discharge ducts of rugged 16 gauge steel can be provided for down flow units. Lateral ducts have integral pencil proof louvres and are available in matching colours.

The HUV Series unit ventilator for concealed or exposed ceiling installations rounds out our family of unit ventilators. The HUV can be installed exposed (below the ceiling), flush mounted or concealed. All of our unit ventilators can be supplied with your choice of steam, water or electric heating coils and DX or water cooling coils. Duct discharge or integral grilles are available.

Engineered Air can also provide any of the models with self-contained DX cooling. This eliminates the need for outdoor condensing units that are subject to vandalism and damage. Using quiet and efficient scroll compressors provides cooling in areas that are occupied year round and allows the central plant to be shut down during idle times.

UV Series

Features

- 4 models to choose from

- Units from 600 to 2400 CFM

- Self-contained DX units available

- Custom built to specific dimensions

- Standard 16 gauge construction (14 gauge optional)

- Electrostatically applied baked polyester powder coat textured paint

- Multiple access panels

- Large piping pockets

- Allen key camlock fasteners

- Standard 14 gauge fan boards and all steel housing with galvanized steel blowers

- Optional slide out fan boards

- 1 inch 3 pound per cubic foot insulation

- Engineered Air manufactured high capacity coils

- Stainless steel drain pans with cross breaks and positive slope

- Efficient permanent split capacitor motors

- Water, Glycol, Steam, DX or Electric Coil options c/w face and bypass if desired

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

RUVG Series Institutional & Commercial Gas Fired Unit Ventilators

- Riser Style Unit Ventilator

- HIgh efficiency indirect fired heat exchanger

- Two stage heating control or modulating (optional)

- ETL Certified (Canada and USA)

RUVG Series

Institutional and Commercial Gas Fired Unit Ventilators

Features

- Heavy duty 16 gauge (1.5mm) steel cabinet.

- Durable textured powder coat finish

- 1” (25mm) acoustic insulation

- Stainless steel drain pan, sloped and insulated, c/w ⅞ (22mm) connection

- Rigid, insulated 14 gauge (1.9mm) fan board

- Large access panels with key operated cam locks & finger pull tabs

- Supply air duct collar discharge

- Mixing plenum with extrude dampers

- Quiet operating direct drive DIDW FC fans

- Multi-speed PSC motors with quick connect

- 2” (50mm) disposable filter

- High efficiency heating and cooling coils

- Wide variety of control options

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

HERESITE for Finned Tube Heating, Cooling and QDT Heat Recovery Coils

The excellent chemical and temperature resistance coupled with the good heat transfer properties of the HERESITE coating have made possible the outstanding results being obtained.

Engineered Air, in searching for corrosion resistant coating for finned tube heat transfer products, realized that HERESITE baked phenolic resins were far superior to any other type of coating on the market, both in terms of heat transfer characteristics and resistance to corrosive attach from an extremely wide range of chemicals.

HERESITE

Corrosion Protection

Description

HERESITE is the registered trademark for pure phenol-formaldehyde thermosetting resinous coatings.

The HERESITE coating applied to finned tube coils is the P-413 Flexible Brown Baking Phenolic Coating. This coating is applied to either aluminum, copper or steel with equal results.

We feel it is important to emphasize that HERESITE baking phenolic coatings are manufactured and sold only by HERESITE PROTECTIVE COATINGS INC. Further, the application of the HERESITE baking phenolic coating to finned tube coils is performed at the HERESITE plant in Manitowoc, Wisconsin, USA, at Engineered Air in Calgary, Alberta, Canada and at other authorized facilities.

Advantages

Practically all typed of finned tube coils used for oil, water, air, gas and process cooling (and heating) as well as a large condensing coils can be HERESITE protected against damaging environments. Currently, the HERESITE coating of air-conditioning and industrial process coils exposed to corrosive fumes and salt atmosphere is in the increase, with many new applications being found.

HERESITE coating offers a more economical solution that special metals for these applications. Typically, aluminum fin coil coated with HERESITE are more economical than copper fin coils. Special metal casing materials are unnecessary since the HERESITE coating is applied to the casing as well as to the finned tubes. Additionally, HERESITE coated aluminum fins will resist attack from most cleaning agents more successfully than copper fin coils.

Application

The present day HERESITE coating of finned tube coils is the result of many years experience during which time application equipment and procedures have been constantly improved. Today, Engineered Air has one of the largest HERESITE facilities in the world. The enables us to HERESITE coat, on a routine basis, coils up to the following size and weight:

- Maximum Fin Dimensions

- 240” long × 78” wide × 18” deep

- Maximum Weight Per Coil

- 4,000 pounds per coil

- Fin Spacing, 1 to 3 tube rows

- 16 per inch maximum

- Fin Spacing, 4 to 6 tube rows

- 14 per inch maximum

- Fin Spacing, 7 and 8 tube rows

- 12 per inch maximum

The HERESITE coating of finned tube coils is accomplished by a multiple coat application of dipping and baking resulting in complete coating coverage of the fins, tubes, headers, casings, etc. Consequently, protection against corrosion is provided for the entire coil. Due to specialized surface preparation techniques plus the good adhesive properties of the HERESITE P-413 coating, it is possible to efficiently HERESITE coat all the usual metals used in fabricating finned tube coils.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

LAMIFLO Series Integral Face & Bypass Coils

Full flow is sent through the coil at all times, preventing freezeup. Temperature control is maintained by a series of Face and Bypass Dampers, spaced evenly over the face of the LAMIFLO. Face dampers are employed on both the entering and eliminate unwated heat pickup.

The use of LAMIFLO Face and Bypass Dampers for makeup air applications has a very distinct advantage over valve control. A coil is selected for the very worst condition possible - and then often oversized. When the outdoor air temperature is much warmer than the design point, but still below freezing, a control valve is often oscillating between cracked open and fully closed. In one of those fully closed moments, it doesn't take long to chill and then freeze the stationary fluid in the tubes.

With LAMIFLO Face and Bypass Dampers, the steam or fluid flow is constant during the period that the outdoor air temperature is below freezing. Temperature control is achieved by metering the incoming cold air through multiple narrow heating and bypass channels to mix at the control temperature. The bypass channels have been sized to provide a pressure drop when fully open that is equal to the pressure drop through the coil, or heating channel when fully open, to assure a constant volume of air. The air streams emerging from the narrow channels are LAMINATED and mixing is virtually complete within 36” (0.9m) of the LAMIFLO section.

The advantage of LAMIFLO over conventional internal or external face and bypass dampers is clean; the homogenous air temperature mix is far superior, and downstream devices, for example, reheat coils, cooling coils, or humidifiers, need not be spaced a great distance from the LAMIFLO section to retain even velocity loading. Air pressure drop is minimal on LAMIFLO coils. Conventional bypass dampers, with all the bypass air passing over top of the heating coil, create a system effect that demands extra horsepower.

LAMIFLO Series

Features

- Uniform heat for makeup air applications

- Steam, hot water or glycol

- Minimizes temperature swing

- Eliminates stratification

- Vertical and horizontal configurations

- Installation in ductwork or Engineered Air units

| Features | Benefits |

|---|---|

| Integral heating coil and bypass sections | Provides safe, even heat for make up air applications |

| Two sets of face dampers (upstream & downstream) | Eliminates coil “wiping”. Mixing is virtually complete within 36” (914mm) |

| Balanced pressure drops in coil and bypass sections | Provides constant air flow at each extreme of operation |

| Coil sections designed for full flow of steam, water or glycol | Maximizes freeze protection |

| Horizontal or Vertical configuration | Accommodates steam, hot water or glycol as well as piping considerations |

| Heavy duty construction | Suitable for commercial and industrial applications |

| Factory assembled and pressure tested. Dampers are set and welded | Assures trouble free operation |

| Optional CSA B51 pressure vessel code certification and construction for resale coils | Accommodates high pressure steam, hot water and glycol applications with copper or steel tubes |

| Optional in house HERESITE coated coils | Provides effective resistance to corrosion of fins, tubes and headers |

| ARI certified ratings of ⅝” water coils | Assures performance based on certified catalog data |

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

AIRTEX Radiant Ceiling Systems - The New Standard in Perimeter Heating

The Airtex extruded aluminum panels in lengths up to 16' (4877mm) have changed the way North America heats its buildings. Clean durable Airtex Radiant Linear products are great for the hospital, school, laboratory and office.

A continuous architectural perimeter band constructed to virtually any panel width from interlocking extrusions.

An innovative mechanical bonding technique maximizes heat transfer between copper circulating coils and aluminum extrusions.

AIRTEX MODULAR PANELS

Airtex Modular Radiant Panels fit in standard acoustic ceiling tile grids and can be placed almost anywhere a regular ceiling tile might go.

An efficient, patented metallurgical bonding technique between copper coil and aluminum sheet.

Panel face can be custom coloured or silk-screened to match acoustic ceiling tile.

AIRTEX Radiant Panels

Radiant Ceiling Systems - The New Standard in Perimeter Heating

Major Applications

-

Educational Facilities

Durable and efficient AIRTEX Panels provide the necessary wall space, occupant comfort and freedom of maintenance desired in al schools.

-

Hospitals

AIRTEX Systems provide ultimate patient comfort in an aseptic environment, with no maintenance.

-

Office Buildings

AIRTEX Systems meet architectural criteria for aesthetics, energy and space efficiency plus easy tenant flexibility.

-

Airports

AIRTEX Systems provide a clean, draftless, uniform environment with unlimited use of perimeter space.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

AF Series Air Cooled Condensers

The Condenser coil is of copper tube / aluminum fin construction as standard although other materials are available as an option. Custom circuiting is utilized to provide optimum capacity with minimum pressure drop.

Proven components, which have withstood the rigorous test of time, are used in the air moving assemblies. Venturi openings are spun to exacting tolerance to insure maximum airflow with minimum horsepower requirements.

All electrical components (standard or optional) are of the highest quality.

AF Series

Air Cooled Condensers

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

Fan Coil Units Direct Drive and Belt Drive

- HFC - Horizontal

- VFC - Vertical

- LFC - Lowboy

Belt Drive Fan Coil Units (Draw and Blow Through) are available in three different models:

- JM - Horizontal

- JMV - Vertical

- MT - Horizontal

Options

- Custom sizes, arrangements and performance ratings

- Recessing flanges and leveling bolts

- Special materials for casings, drain pans, coils and fans

- High static pressure models

- Extra heavy 16 GA (1.5mm) construction (standard on exposed units)

- High density, acoustical insulation, 3 lb/ft^3 (48 kg/m^3) with neoprene coating

- Throw away, permanent washable or replaceable media filters

- Special motors: totally enclosed, special voltages

- Auxiliary hot water, steam or electric heating coils

- Extra high capacity cooling coils

- Unit or remote mounted, variable or 3 speed controllers, thermostats and starters

- Valve control packages

- Ultra quiet design

Direct Drive Fan Coil Units

Models: HFC, VFC and LFC

| Cabinets | Concealed units shall be fabricated with heavy 18 gauge (1.2mm) satin coat galvanized steel. Exposed units shall be 16 gauge (1.5mm) galvanneal steel and be treated to a multi-step preparation process before the application of an electrostatically applied, baked white powder coat primer. Cabinets shall be lined with 1" (25mm) neoprene coated insulation. Condensate pans shall be stainless steel and be insulated with closed cell insulation for sweat proof operation and corrosion resistance. All units shall come complete with a 1" synthetic disposable filter, as well as being equipped with an electrical junction box. |

| Coils | Heating and cooling coils shall be manufactured by Engineered Air and consist of aluminum fins mechanically bonded to 1/2" (13mm) copper tubes. Fins shall be rippled for maximum heat transfer and coil casings shall be galvanized steel. Coils shall be factory tested with air at 300 psig (2070 kPa) while immersed in an illuminated water tank. |

| Fans | Double width, double inlet, forward curved centrifugal fans constructed of galvanized steel shall be provided. Fans shall be balanced for quiet, vibration free operation and be supplied with housing specifically designed for efficient airflow. |

| Motors | All motors shall be open type, resiliently mounted, incorporating sleeve bearings and internal overload protection. Motors shall be permanent split capacitor type. All motors shall be equipped for 115/1/60 and be capable of at least three speeds. |

| Approval | All units shall be safety tested to conform to UL Standard 1995 and CSA.2 No. 236. Units shall be CSA approved and bear the CSA label. Units shall be Engineered Air series HFC (horizontal blow thru), VFC (vertical blow thru), or LFC (lowboy blow thru) with model, sizes, capacities, motor types, H.P. (kW) and power characteristics as indicated on drawings and/or schedules. |

Belt Drive Fan Coil Units

Models: JM, JMV and MT

| Cabinets | Casing shall be constructed of 18 gauge (1.3mm) unpainted satin coat galvanized steel. Units shall include 1" (25mm) 1 1/2" lb/ft^3 (24 kg/m^3) insulation, integral stainless steel drain pan, slotted hanger channels, duct collars on inlet and outlet, screwed access panels, adjustable motor mounts and 2" (50mm) throwaway filters. Unit construction is one piece. Units are factory tested. Field assembly of components, including mounting of motor and drives is not acceptable.. |

| Coils | Heating and/or cooling coils shall be 1/2" (13mm) copper tube with rippled aluminum fins and Schraeder vent fittings on fluid coils. D.X. coils shall include distributors. Expansion valves and refrigeration accessories are by refrigeration contractor (others). |

| Approval | All units shall be safety tested to conform to UL Standard 1995 and CSA.2 No. 236. Units shall be CSA approved and bear the CSA label. Units shall be Engineered Air model JM (draw through), JMV (vertical draw through), or MT (blow through) with model number, sizes, capacities, motor types, H.P. (kW), and power characteristics as indicated ond rawing and/or schedules. |

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.