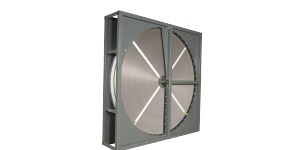

NTM Series

No-Through-Metal Air Handler Panels

A premium engineered equipment panel system. Specially designed for low temperature air handling units to prevent condensation from forming on the exterior panel and to reduce heat gain or loss. Features a concealed fastening system and a non-CFC polyurethane insulating core.

Applications

Engineered Air’s NTM Series air handling unit panels are architecturally designed to complement the building envelope, while providing enhanced thermal insulation, particularly for outdoor units, but also for indoor applications where low temperature air is created within the air handler. The superior joint engineering assures an air tight, moisture resistant enclosure for air handlers and packaged HVAC equipment.

Construction

NTM Series panels are insulated with a non-CFC thermosetting polyurethane insulation that meets model building code specifications. Structural grade steel facings are precisely roll formed and foam insulation is expanded between the metal sheets in a state-of-the-art continuous production sequence that is fully computerized to ensure optimum quality and consistency in every panel.

Insulation

NTM “No-Through-Metal” Series panels with foamed polyurethane insulation is offered in 2” thickness. 4” thick panels are available at extra cost, an extended delivery.

Facings

NTM Series panels are faced with 26 gauge stucco embossed galvanized steel to ASTM-525 G-90 designation. Base steel shall be structural quality to minimum Grade A 33,000 psi, conforming to ASTM A-446. Optional panel facings of Galvalume, aluminum or stainless steel are available at extra cost and extended delivery.

Coating Systems

NTM Series panels are primed both sides with a 0.2 mil primer and finished on one or both sides as specified, with one of the following finishes:

- Electrostatically applied alkyd enamel: supplied in Aluminum Gray as standard, or colour to suit.

- Two part epoxy enamel with clear coat glossy finish. Approved for food contact areas in a limited range of colours.

Above finishes and colour options are at an extra cost.

Fire

Meets special requirements of model building codes and is certified and approved by the following authorities:

UL: Underwriters Laboratories Inc.

ULC: Underwriters Laboratories Canada

FM: Factory Mutual

WH: Warnock Hersey

NYFC: New York State Toxicity Standard

FM-4880: Class 1 Fire Rating

ASTM-E84: Flame Spread: 17 | Smoke Developed: 97

ULC-S102: Flame Spread: 22 | Smoke Developed: 67

UBC 17-6: Passed multi-storey test with standard panels

Thermal Properties Standard 2” panel

Transmission: 0.061 BTU/hr × ft² × °F (including air films)

Resistance: 15.6 °F × ft² × hr/BTU (panel only – no air films)

Vapor Barrier

ASTM E-238: Air Infiltration: 0.0015 CFM/ft² at 20 psf

ASTM E-331: Water Penetration: “0” at 20 psi

Structural

ASTM E-72: Vacuum chamber tested for wind and suction load deflections on wall assemblies

ASTM E-72-9: The panel achieved a vertical load bearing capacity on standard width to maximum 19,800 lbs. compressive force at 0.06” deflection

Fatigue Test: Standard panels were tested for long term deflection failure. The panels exceeded 2 million cycles without failure or deformation

Bond Strength: The panel was tested for Tensile Bond Strength of the metal-to-foam interface to more than 1200 lb. force without delamination.

Allowable Uniform Loads (PSF) for Maximum Deflection 1/180th of Span Length

| Thickness | Span (feet) | |||||||||||||||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |

| 2” Std. | 71.1 | 56.1 | 45.2 | 37.1 | 30.9 | 25.9 | 22.0 | 18.7 | 16.2 | 14.0 | 12.1 | 10.4 | ||||

| 4” Opt. | 121.9 | 98.8 | 82.2 | 69.6 | 59.8 | 51.9 | 45.4 | 40.0 | 35.5 | 31.6 | 28.2 | 25.2 | 22.5 | 19.8 | 17.9 | 15.9 |

Note: to determine static pressure within cabinet, multiply allowable loading in PSF by 0.192.

Example: 2’ panel with a 10 foot span can withstand an internal static pressure of 25.9 × 0.192 = 5.0”w.g.

If snow load or internal static pressure exceeds the unsupported span length,

an intermediate structural support will be provided to reduce excessive deflection.

*Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.