NEXTGEN CENCON

Digital Controller

The CENCON controller is the advanced operational component for the majority of custom manufactured Engineered Air HVAC equipment. Various expansion modules (-XM) may be added to the CENCON to extend the operational capabilities to gas fired heating, cooling, humidification, dehumidification, and energy recovery systems. It is the highest level of the Engineered Air control family and can easily manage a wide range of applications, from simple burners to complex air handling units with multiple air treatment processes.

Technical Data

- BACnet certified networking built in

- Uses tried-and-true Engineered Air control logic

- Easily expandable control options with expansion modules (see below)

- Full featured status display & adjustment on controller or on PC (direct ethernet)

- No subscription cost

- Power supply: 24 VAC

The CENCON control line has been designed to:

- Provide precise control, while also incorporating operating and safety limits.

- Eliminate electro-mechanical devices (switches, relays, etc.) by means of logic-based programming.

- Provide rugged, dependable controllers that can withstand the rigors of a rooftop installation; the ability to operate at -40°F ambient and in the presence of electronic noise is essential.

The CENCON can be connected to any Engineered Air expansion module. The expansion module provides the required wiring terminals for each additional appliance it is controlling. Available expansion modules are shown below:

C-XM

The C-XM expansion board provides cooling control, intended for use with packaged direct expansion cooling units or packaged air handlers with remote condensing units.

J-XM

The Engineered Air DJ Series indirect fired burners offer superior turndown and modulates both gas firing rate and combustion air quantity. The J-XM expansion board controls any of the DJ series burners.

The J-XM can be packaged with other expansion modules for multipurpose units (i.e. packaged heating and cooling, humidification/dehumidification, heat recovery, etc.).

CD-XM

The CD-XM is a combustion motor speed drive that acts as a speed sensor for combustion motors used with indirect-fired equipment. This helps provide consistent comfort in DJ and large SH indirect fired burners. It works in conjunction with the J-XM CENCON modules.

G-XM

The G-XM expansion module is an industrial furnace controller that has been designed to provide accurate control for indirect-fired burners, with particular emphasis on allowing the burner to turn down to its full capability while maintaining acceptable flue-gas properties.

Together the DG high turndown burner and the G-XM controller provide optimum air heater performance.

H-XM

The H-XM controller has been designed to control staged electric heat applications. It utilizes a proportional-integral control strategy to sequence five binary style output stages.

The electric heat coil controlled by an H-XM controller is specifically designed with stages sized for operation with the binary control logic. Up to fifteen “equivalent” control stages are created (7 or 11 equivalent stages can also be provided.)

ER-XM

The ER-XM expansion board controls various heat recovery products installed in Engineered Air units. These include the HRA Air-to-Air Heat Exchanger, QDT Heat Recovery Pipe, and HRW Heat Recovery Wheel.

The ER-XM helps these units achieve their goals by controlling the rate of heat transfer to provide a set output temperature and provide frost prevention.

M-XM

The Engineered Air M-XM expansion board is designed to control Engineered Air HE Series direct fired burner on make up air units. The M-XM controller provides temperature control and airflow monitoring. A dual sensor option is built in the M-XM controller to provide an even discharge temperature.

The M-XM provides interlock between the exhaust fan and the make up air unit. This allows the M-XM to prove the operation of both the exhaust fan and supply fan. Reverse interlock is also available to prevent negative building pressure during startup.

P-XM

Engineered Air’s P-XM pressure sensing module works alongside the M-XM to monitor the direct fired burner profile pressure drop. This expansion module plays an integral role in the HE product line.

The P-XM can also be used independently of the M-XM as a clogged filter switch, an air proving switch, and an air pressure sensor.

S-XM

The S-XM controller has been designed to control Engineered Air SH Series of gas fired humidifiers. It utilizes a proportional-integral control strategy to modulate relative humidity levels.

The Engineered Air S-XM controller provides water level, burner, humidity and system status control. The S-XM has a built-in drain cycle timer that will initiate a drain cycle depending on the firing rates of the burner. A mixing valve is also incorporated in the S-XM to eliminate high drain temperature.

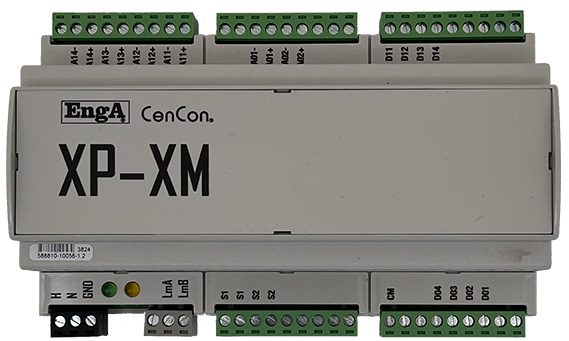

XP-XM

The XP-XM expansion module allows for BACnet monitoring of additional Input and Output points. Each XP-XM has 2 temperature sensor inputs, 4 analog inputs, 4 digital inputs, 2 analog outputs and 4 digital outputs. Up to 4 of these modules can be used on a single CENCON controller for an increased number of available I/O points.

*Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.